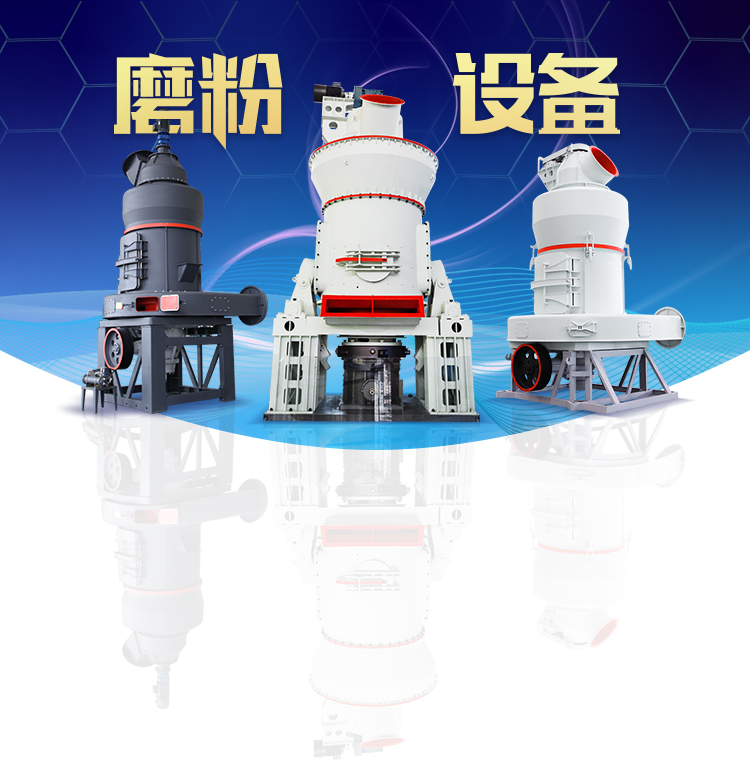

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

The Workings Of Roll Mining Mill

Introduction to Rolling Process Cambridge University

2015年11月19日 The entire assembly of the rolls mounted on bearings is held in bearing blocks (called chocks), which in turn are held between the gaps of two cast frames (called housings), complete with roll gap adjustment facilities and roll driving arrangement The How do Rolling Mills Function? Rolling mills always use a minimum of two rollers, regardless of the number of rollers used A set of rotating rollers grips the material and propels it forward as it moves through the process Rolling Mills Types, Function, Material2023年7月4日 HighPressure Roller Mill The highpressure roller mill, also called the roller presser or the extrusion mill, is a grinding equipment based on the principle of material Roller Mill Springer2015年11月19日 Principles and Applications of Metal Rolling This is a book written by a practitioner It is somewhat different from a normal textbook involving machines and Principles and Applications of Metal Rolling

.jpg)

Metal Rolling SpringerLink

Rolling is the most commonly used and economical metal forming process Metal rolling involves squeezing a metallic workpiece between two rotating rolls, which exert Rolling mill work rolls impart the rolled strips with their finished surface quality In order to make this repeatable, the roll surface quality must retain its asground surface for as long Rolling Mill an overview ScienceDirect Topics2008年10月21日 Chapter 14 Operations Operation of Rolling Mills Rolls are the tools of the rolling trade and the way they are used to execute their duty of deforming steel is in Operation of Rolling Mills rolldesigns2016年6月5日 The entire assembly of the rolls mounted on bearings is held in bearing blocks (called chocks), which in turn are held between the gaps of two cast frames (called housings), complete with roll gap Introduction to Rolling Process (Chapter 1)

.jpg)

Rolling mill control: architecture and applications IEEE Xplore

1998年3月4日 Rolling mill control: architecture and applications Abstract: Considers some of the distributed aspects of the control of modern metal rolling mills Such mills have a 2023年6月19日 Sendizmer roll mill: Sendizmer is a clustered form of roll arrangement used to produce thin foils and sheets With this arrangement, strong metals can be rolled with ease With this process, we can attain Rolling of Metals in Mills: Definition, Types, 2017年6月2日 The rolls can be serrated, toothed or smooth Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers Impact mills are used to pulverize feed material by impact How it Works: Crushers, Grinding Mills and 2005年9月15日 The surface roughness of commercially used work rolls in cold mills and temper mills vary from a low of 02 to a high of 5 μm [17] The contribution of the work roll's roughness to the success of tribological phenomena along with the actions of the emulsions during the process need to be examinedThe effect of roll roughness and lubricant viscosity on the

The story of Cornish tin mining British Heritage Travel

2024年7月1日 Mining history Since 2006, 48,700 acres of Cornwall and West Devon’s mining landscape has been inscribed as a UNESCO World Heritage Site Focused on the key period 1700 to 1914, when metal mining provided the raw materials to feed Britain’s Industrial Revolution and pioneered farreaching technological developments, the site 5 天之前 The first largescale mining began in the Johnstown area when the Cambria Iron Co opened the Rolling Mill Mine in 1856 The Rolling Mill Mine, located off Route 56 on the hillside next to the Johnstown Inclined Plane, covered the largest area in the nation worked by a single opening In 1922, it covered 10 square miles and the farthest working Rolling Mill Mine Disaster Conservation Heritage2 Rolling Cluster Mill: ( Types of Rolling Mills ) A rolling mill with four levels is known as a cluster rolling mill Each of the two working rolls within this rolling mill is backed by two or bigger backup rollers that can roll rigid materials Rolls with a minor diameter but a very long length may be required to get the effect soughtRolling Mills Types, Function, Material Engineering Learn2015年1月1日 Another way to avode the roll bending is the rolling with rolls put in the electromagnetic field [5] External rolls are made hollow Special pistons are mounted into the rolls with ability to move along the roll axis both jointly and separately (figure 3) In this way, rolls can form different forms and sheet thickness depending on pistons The Work Roll Bending Control System of the Hot Plate Rolling Mill

Vertical roller mills: The new leader in grinding technology

2019年10月11日 Mining companies today face a completely new battery of challenges to recover minerals Historically the reefs were rich and large profits were made with ordinary recovery circuits but today mines are dealing with complicated ores that require fine grinding to allow a 92% – 98% recovery rate just to stay in the game Read more about gold mining5 天之前 The largest physical disturbances at a mine site are the actual mine workings, such as open pits and the associated waste rock disposal areas Mining facilities such as offices, shops, and mills, which occupy a small part of the disturbed area, are usually salvaged or demolished when the mine is closedHow can metal mining impact the environment?2018年12月5日 The Story Of Mine Mill : Code Switch Reporter Julia Simon tells us about a radical miners' union in Birmingham, Alabama It laid the foundation for civil rights organizers in the South, and holds The Story Of Mine Mill : Code Switch NPR2019年10月17日 In this post, we're going to learn more about rod mill We'll cover it from two aspects: 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common The Working Principle and Structure of Rod Mill

.jpg)

Rolling Mills: 6 Different Types of Rolling Mills

2024年8月10日 In the rolling process, the job is drawn through a set of rolls due to interface friction, and the compressive forces reduce the thickness of the workpiece or change its crosssectional area The types of rolls used Rolling Aluminum: From the Mine to Mill Rolling Aluminum: From the Mine to Mill This publication was developed for educational purposes and provides a broad description of how aluminum sheet and plate fabricated products are manufactured in an aluminum sheet mill It enlarges upon the information presented in the video of the same nameRolling Aluminum: From the Mine to Mill2023年10月10日 This mine uses several SAG mills as part of its operations to produce over 1 million tonnes of copper annually In addition, there are other notable examples such as Grasberg Mine in Indonesia and Collahuasi Mine in Chile that utilize SAG mill technology extensively for their mining operationsUnderstanding the SAG Mill in Copper Ore Mining Process2015年3月23日 Old Mill Dam Mine at Great Hucklow was originally worked for lead until 1885 At that time miners discarded other minerals they found as waste, but it is now these spoils and discarded veins that are rich pickings, financially viable in the 21st century mineral market Old mine workings are generally marked on mine plans but test drilling Going underground in Derbyshire’s only remaining lead mine

From Quern to Computer: The history of flour milling Mills

2016年9月6日 Dee Mills, Chester, a ‘famous feudal mill’ (postcard from Mills Archive Collection, WPACWAT00032) Bennett and Elton described their work as ‘an attempt to collate the scattered muniments of the industry, ancient and modern, and frame them in intelligible form: eventually preparing the way, perhaps, for something better qualified to 2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Grinding Mills — Types, Working Principle Applications2021年8月30日 Sometimes, a product cannot be contaminated from the iron of the steel balls In this instance, a pebble mill steps in; rock pebbles, either quartz or silica, provide a friction source along with ore particles HighPressure Grinding Rolls For mills wanting to replace ball mills, highpressure grinding rolls are often the answer They can The Importance of Industrial Grinding Equipment in Mining2013年11月29日 Many urban environments are located in regions where mining has occurred and abandonment has left a legacy of old workings and mine entries, many of which may still be uncharted and can be hazardous to development The many aspects of mining and other human activity that give rise to potential geohazards are reviewed Site Impacts of abandoned mine workings on aspects of urban development

Four Types Of Rolling Mills Metal Processing

2024年7月31日 This mill consists of a pair of heavy backing rolls surrounded by a large number of small planetary rolls The main feature of this mill is that it hotreduces a slab to coiled strip in a single pass The 2023年5月31日 Definition of a Rolling Mill Generally, a rolling mill refers to a machine used in metalworking works or projects to shape metal materials by passing them through a pair of rolls Similarly, these machines’ main A Definitive Guide to Rolling Mills: All You Need Määritelmät Verbit (transitive) To grind or otherwise process in a mill or other machine (transitive) To shape, polish, dress or finish using a machine (transitive) To engrave one or more grooves or a pattern around the edge of (a cylindrical object such as a coin) (intransitive, followed by, around, about, etc) To move about in an aimless fashion mill suomeksi Sanakirja (englantisuomi)Routes to thick films Robert Dorey, in Ceramic Thick Films for MEMS and Microdevices, 2012 261 Roll mill Two counterrotating rollers made of hard materials crush the powder that passes between them It is possible to obtain powder sizes down to approximately 10 μm Due to the coarse size of the powder obtained, this form of rolling is rarely used for Roll Mill an overview ScienceDirect Topics

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

2017年9月26日 5 >> UNDErsTaNDINg MINE TO MILL Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 years Implemented effectively, numerous operations have experienced productivity gains from Mine to Mill in the range In a typical mill, there may be up to four break rollers (that shear open the wheat seeds and then further break open already sheared wheat) and 12 reduction rolls Some particles of flour will pass through just one break roll and one reduction roll, while those closer to the layers of bran and germ will pass through multiple rollsThe milling process UK Flour Millers2015年5月13日 Underground mine backfilling is a form of ground improvement that has to be carried out in the mine sites The backfilling provides ground support and regional stability, thus facilitating ore removal from nearby regions The large underground voids created by the ore removal are backfilled with the waste tailings in the form of paste fills, Underground Mine Backfilling in Australia Using Paste Fills 2023年6月9日 Grassington Moor lead mining trail This is a waymarked route that takes you up the long road from Grassington to the moor It takes in a wheelhouse, smelt mill, chimney, engine shaft and more The trail is dotted with information panels where you can learn all about the history of the area Greenhow lead mining trail and the Coldstones CutExplore the history of lead mining in the Yorkshire Dales

.jpg)

(PDF) Gold Mineralization in the Rhodesdale Gneiss south

1987年1月12日 Gold mining in the granitegneiss terrain south and east of Kadoma has continued without interruption since the turn of the century and has given rise to numerous profitable smallworkings as well 2021年5月10日 The more commonly designated rollingmill parts include rolls, housings, roller table, manipulator, guides, guards, passes, and collars Several of these parts have been mentioned Fig 47 shows the outline of a pair of rolls with examples of typical passes between the rolls156 Names Of RollingMill Parts ChestofBooks2023年6月19日 Sendizmer roll mill: Sendizmer is a clustered form of roll arrangement used to produce thin foils and sheets With this arrangement, strong metals can be rolled with ease With this process, we can attain Rolling of Metals in Mills: Definition, Types, 2017年6月2日 The rolls can be serrated, toothed or smooth Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers Impact mills are used to pulverize feed material by impact How it Works: Crushers, Grinding Mills and

The effect of roll roughness and lubricant viscosity on the

2005年9月15日 The surface roughness of commercially used work rolls in cold mills and temper mills vary from a low of 02 to a high of 5 μm [17] The contribution of the work roll's roughness to the success of tribological phenomena along with the actions of the emulsions during the process need to be examined2024年7月1日 Mining history Since 2006, 48,700 acres of Cornwall and West Devon’s mining landscape has been inscribed as a UNESCO World Heritage Site Focused on the key period 1700 to 1914, when metal mining provided the raw materials to feed Britain’s Industrial Revolution and pioneered farreaching technological developments, the site The story of Cornish tin mining British Heritage Travel5 天之前 The first largescale mining began in the Johnstown area when the Cambria Iron Co opened the Rolling Mill Mine in 1856 The Rolling Mill Mine, located off Route 56 on the hillside next to the Johnstown Inclined Plane, covered the largest area in the nation worked by a single opening In 1922, it covered 10 square miles and the farthest working Rolling Mill Mine Disaster Conservation Heritage2 Rolling Cluster Mill: ( Types of Rolling Mills ) A rolling mill with four levels is known as a cluster rolling mill Each of the two working rolls within this rolling mill is backed by two or bigger backup rollers that can roll rigid materials Rolls with a minor diameter but a very long length may be required to get the effect soughtRolling Mills Types, Function, Material Engineering Learn

.jpg)

The Work Roll Bending Control System of the Hot Plate Rolling Mill

2015年1月1日 Another way to avode the roll bending is the rolling with rolls put in the electromagnetic field [5] External rolls are made hollow Special pistons are mounted into the rolls with ability to move along the roll axis both jointly and separately (figure 3) In this way, rolls can form different forms and sheet thickness depending on pistons 2019年10月11日 Mining companies today face a completely new battery of challenges to recover minerals Historically the reefs were rich and large profits were made with ordinary recovery circuits but today mines are dealing with complicated ores that require fine grinding to allow a 92% – 98% recovery rate just to stay in the game Read more about gold miningVertical roller mills: The new leader in grinding technology5 天之前 The largest physical disturbances at a mine site are the actual mine workings, such as open pits and the associated waste rock disposal areas Mining facilities such as offices, shops, and mills, which occupy a small part of the disturbed area, are usually salvaged or demolished when the mine is closedHow can metal mining impact the environment?2018年12月5日 The Story Of Mine Mill : Code Switch Reporter Julia Simon tells us about a radical miners' union in Birmingham, Alabama It laid the foundation for civil rights organizers in the South, and holds The Story Of Mine Mill : Code Switch NPR

制粉机械1065雷蒙磨安装尺寸制粉机械1065雷蒙磨安装尺寸制粉机械1065雷蒙磨安装尺寸

--YKF粉碎设备

--重庆圆盘锯生产厂家

--露天开采涉及费用

--碳酸钙型号有几种

--碳酸钙类改良土比例

--鹅孵石棒磨雷蒙磨

--天津哪里能买到日月潭滑轨天津哪里能买到日月潭滑轨天津哪里能买到日月潭滑轨

--矿石磨粉机用什么轴承

--山沙开采证办理

--中国雷蒙磨厂

--大田县滑石粉研磨机,石矿设备

--方解石90kw无烟煤褐煤磨粉机维修与保养

--矿粉.白泥砾石的比重矿粉.白泥砾石的比重矿粉.白泥砾石的比重

--40TPH青石

--国务院关于加快培育和发展战略性新兴产业的决定

--钢铁厂煤粉制备磨粉生产线

--石膏粉碎器产量520TH

--长春市双阳

--雷蒙磨选用立式辊磨机好还是重晶石磨粉机好

--花岗石石材加工机械的价格

--雷蒙磨250400目

--粉磨机窑砖厂全套设备,真空粉磨机

--鄂重重型机器有限公司

--石膏砖生产机器

--工业磨粉机厂家lm150k立式磨

--2ya2460高细立磨的使用

--煤炭深加工技术装备煤炭深加工技术装备煤炭深加工技术装备

--石灰石渣煤渣立式磨所需的油

--哪些石头可以生产建筑骨料

--