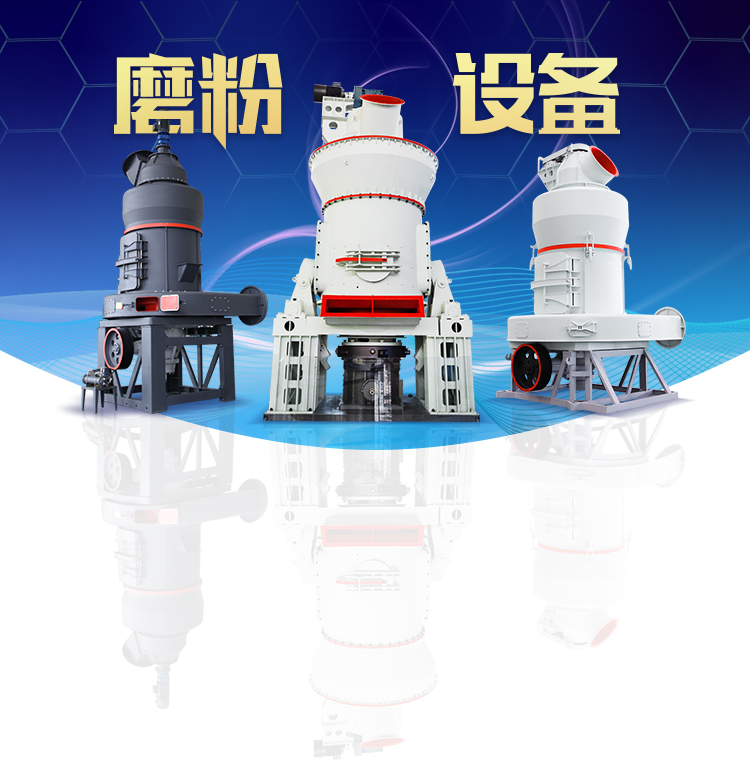

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Crusher Plant Capacities Chart

.jpg)

Stone Crusher Plant Design: Best Practices for

2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance 19 行 A grid chart or curve for the selected crusher shows that, for a 2½ Crusher Efficiency Calculations 911Metallurgist2020年3月4日 Horsepower requirements vary with feed material characteristics, crusher feed size, desired product size, crushing chamber configuration, impeller table speed and ISC® VSI Crusher Models and CapacitiesThe capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft These capacity tables show several significant differences between the two common types of primary Estimate Jaw Crusher Capacity 911Metallurgist

Mobile Stone Crusher Plant: Efficient Crushing

1 天前 14:04:11 Baichy A mobile stone crusher plant is a portable equipment designed for crushing stones and rocks It consists of various components such as a crusher (usually jaw crusher, impact Contribute to chengxinjia/sbm development by creating an account on GitHubsbm/sbm crusher plant capacities chartmd at main GitHub2022年11月21日 Crushing plant The crushing plant reduces the mined material to a conveyable size thyssenkrupp Industrial Solutions offers a wide range of crushing units crushing and conveying systems ThyssenKrupp2024年8月29日 It starts by describing the main design idea of crushing and screening plants It is important to understand the purposes of the different crushing stages in a CRUSHING PLANT PROCESS OPTIMISATION AusIMM

.jpg)

Crushing it: A Comprehensive Guide to Stone

2023年2月28日 Discover the different types of stone crusher plants, their environmental impact, maintenance requirements, and case studies of successful operations Get answers to frequently asked questions and Crushing Screening Plant Assessment Example Capacities and Horsepower of Jaw Crushers (tons/hr) Typical Capacities of TwinRoll Crushers (tons/hr) have the needed capacity a jaw crusher like the Crusher Efficiency Calculations 911Metallurgist2016年3月10日 Short Head (Tertiary) Cone Crusher (Refer to Fig 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In)Crushing Plant Flowsheet DesignLayout 911 Metallurgist2023年2月24日 Estimated Cost of Setting Up a Stone Crusher Plant The cost of setting up a stone crusher plant varies depending on the factors mentioned above Generally, the estimated cost to set up a stone Stone Crusher Plant Setup Cost: Factors,

Selecting the right crusher for your operations Quarry

2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)2016年4月14日 equipment is selected to meet or exceed the capacities Design criteria can be calculated from a simple spreadsheet as shown in Table 2 can all affect crusher plant design Construction costs are generally much greater at high altitudes, in cold climates and at remote sites To improve the economics of such locations, modular and pre Crushing Plant Design and Layout Considerations 911 2019年7月9日 CRUSHER CAPACITIES IN TONS [TONNES] 125 275 150 275 100 275 200 150 275 200 200 200 230 230 220 230 250 250/300 250 250 300/350 220 210 210 210 190 LIPPMANN HEAVYDUTY JAW CRUSHER DIMENSIONS Lippmann Milwaukee, Inc 3271 East Van Norman Avenue Cudahy, WI 531100586 (800) 6480486 • (414) 7442565HEAVYDUTY JAW CRUSHERS MidStates AggA welldesigned plant layout balances the capital versus operating cost over mine life Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant a welldesigned project flowsheet specifies tonnage requirements and the equipment is selected to meet or exceed the capacities REQUEST MORE Crushing Plant Design and Layout Yeco Machinery

Cone crusher basics in 4 minutes SRP

Sandvik CH cone crusher The open side and closed As the feed is crushed, it falls and exits the crusher through the space at the bottom The eccentric gyration of the mantle means that at any moment this space is narrowest at one point, and widest at the opposite point The widest distance is known as the open side setting (OSS) and the Check the aggregate crushing plant process flow chart below 200tph mobile crusher plant for aggregates 150TPH Mobile Sand Making Plant For Quartz Sand Production Configurations: APG3895W (vibrating feeder) + APJ6090E The mobile crushing plant capacities range from 45tph to 500tph tire typeAggregate Crusher Plant in The Philippines 10 ~ 1000 tph2022年7月1日 Palm Kernel Crusher Plant Operation kernel, followed by screwpressing whereas plants with larger capacities (50500 t day1) usually pretreat the kernel completely before screwpressing as described Mechanical palm kernel crushing process flow chart Figure 5 Mechanical screw press for palm kernel oil extractionPalm Kernel Crusher Plant Operation and Economic 2016年2月26日 method for calculating capacities using a Dodgetype jaw crusher The equation proposed by Hersam includes a number of constants that are only qualitatively related to the machine and material characteristics These constants in clude items such as speed, throw, setting angle between the jaws, size and nature of the materialCapacities and performance characteristics of jaw crushers

.jpg)

Jaw Crusher: Range, Working Principle,

2022年2月22日 A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top Contribute to chengxinjia/sbm development by creating an account on GitHubsbm/sbm crusher plant capacities chartmd at main2023年8月2日 Crusher machines come in a wide variety of sizes and capacities, from small jaw crushers that cost the same as a new truck to extra large cone crushers that cost millions of dollars whether that be transport to additional crushers or to a wet processing plant It is the first stage in the crushing process that can sometimes include Types of Crushers: What You Need to Know HUATAO GROUP4 天之前 The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications from 40200 tonnes per hour and is ideal for working in a composite crushing arrangement with Parker primary crushing plants, screens and Impact Crushers Parker Plant

Mobile Crusher Plant CostSaving, High Mobility, Safety

6 天之前 Processing capacity: up to 200tph Configurations: 200Kw impact crusher + 1536 type return screen Maximum feeding: 350 medium soft rock Crushing materials: medium and soft rock and construction waste Applications: construction aggregate or road construction Each module is compact and efficient, hydraulic assisted in many places, with return Whether it is primary, secondary or tertiary crushing, dump fed or metered, our sturdy, versatile Sizers have been expertly designed to handle many different materials and throughput capacities Not only are Sizers insensitive to soft, wet and sticky material, but they can also process hard, abrasive rock either separately or combined Discover Sizers MMD2024年7月10日 The hydraulic cone crusher according to different performance is divided into single cylinder hydraulic cone crusher and multi cylinder hydraulic cone crusher discharging mouth size, capacity and product size by measuring instrument and sensor with digital, chart display The operator checks and adjusts the working condition of equipment Specification of Hydraulic Cone Crusher2013年3月16日 1Kernel crusher can Crush peanut, almond as well as other kernels into 1~3mm granular 2automatic chrome ore processing plant; gold crushing process;kernel crushing plant process flow Mining Quarry Plant

Nordberg HP Series cone crushers – High performance

2023年1月20日 convenient and safe The crusher is easy to open, it has a very effective tramprelease system, and it clears the cavity efficiently With the HP Series, you can rotate the bowl of the crusher open for easy liner changes using the hydraulic motor The hydraulic motor also rotates the bowl to adjust the crusher settingIn Figure 2 6, shape distribution curves are shown for limestone crushed in a cone crusher and in an impact crusher (fixed blowbar impact crusher) The result supports the theory that crushing Threestage crushing plant Download Scientific DiagramFor stationary concrete plant, we call them AJ series concrete plant; while, for mobile type, we name them as AJY series concrete batching plant Malaysia As for its capacity, 25 ~ 90 m3/h capacities are available for Batching Plant for Sale in Malaysia Aimix 2023年12月24日 equipment is selected to meet or exceed the capacities Design criteria can be calculated from a simple spreadsheet as shown in Table 2 can all affect crusher plant design Construction costs are generally much greater at high altitudes, in cold climates and at remote sites To improve the economics of such locations, modular and Crushing Plant Design and Layout Considerations MINE

SANDVIK JAW CRUSHER SERIES Sandvik Mining and

2020年4月1日 SANDVIK JAW CRUSHER SERIES HIGH CAPACITY JAW CRUSHERS AND LOW COST PER TON Sandvik’s topoftheline CJtype jaw crushers are specifically built for your primary applications where resizing is the key objective They allow the material to be processed within your crushing plant To ensure optimum performance, the jaw 2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant2021年9月9日 200t/h crushing and sand making plant Specifications of products: 05mm, 516mm, 16315mm Equipment configuration: PE750*1060 jaw crusher, PFW1315III impact crusher, 3Y2160 vibrating screen 400t/h sand making plant Equipment configuration: PE1000*1200 jaw crusher, PFW1315III impact crusher (2 pcs), VSI1140 Limestone Mining ProcessSBM Industrial Technology GroupQuartz crusher is a mechanical equipment used to crush quartz stone and some other similar materials It uses advanced technology and innovative design to process quartz stone into 040mm quartz gravel and 05mm quartz sand that can be used in mining, construction, highway construction and other engineering projects Next, let’s take a look Quartz Crusher Quartz Crushing Equipment for Quartz Sand

Quartz Crushing Plant Royal Engineering

2024年9月4日 As a leading Quartz Crushing Plant Exporter, we offer a wide range of crushing plants with varying capacities to cater to the diverse needs of our clients Our plants are equipped with advanced technology and modern features, making them userfriendly and easy to operate Static Crushing Plant; Mobile Crusher (Wheel Based/ Lokotrack In a tough environment, you need robust equipment that won’t let you down The Double Roller Crusher is a heavyduty machine designed to withstand the rigours of the mining industry With high capacities and minimum downtime, this rolling crusher is ideal for both soft and mediumhard rock crushing applicationsDouble Roll Crusher DRC FLSmidth2024年3月1日 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to horizontal impact crushers The rotor's high flywheel mass enables the singlestage shredding of feed pieces with edge lengths of up What Machines Do Stone Crushing Plants Need? Fote The QJ331 jaw crusher further develops the very latest technology used within the Q range ofdata output of all plant operating parameters•Improved loadHeight415 m 13' 7½”Standard Weight46,860 kg 103,310 lbsPerformanceOptimum Feed Size560 mm³ 22 inch³Capacity (up to)300 tph 336 en/123/dimensions of tph crusher plantsmd at main

Stone crushing screening plant of 250 TPH unisbm

Stone crushing plant Flow chart: SBM 250TPH 300 TPH stone crushing screening plant is our small and medium scale crusher plant It is mainly consist of ZSW490×130 Vibrating Feeder, PE900×1200 Jaw crusher, PF1315 Impact crusher, and 3YA2160 Vibrating screen SBM can design the stone crushing plant flow chart according to the raw materials2023年2月28日 Double toggle jaw crushers are used in larger plants and have higher capacities, but they are more complex to operate and maintain FAQs What is a single toggle jaw crusher, and how does it differ from a Primary Jaw Crusher – Everything You Need to 2016年1月26日 equipment is selected to meet or exceed the capacities Design criteria can be calculated from a simple spreadsheet as shown in Table 2 can all affect crusher plant design Construction costs are generally much greater at high altitudes, in cold climates and at remote sites To improve the economics of such locations, modular and pre Crushing Plant Design and Layout Considerations 911 Jaw crushing plant / mobile PX200 Mining and crusher production capacity of twistpotatoin The feed materials include ore coal oil sands limestone gypsum and chalk while in terms of the values and features this item supports turnkey projects of customized semi mobile crushing plants with various high capacity applications Finally the significantly less crusher plant capacities values

43.jpg)

Impact crusher thyssenkrupp Polysius Crushing Technologies

Impact crusher Crushers for medium hard material Experience the evolution of innovation with thyssenkrupp Polysius Inspiring engineering excellence semimobile or mobile crushing plants with plant capacities of more then 4,000 t/h Contact thyssenkrupp Polysius GmbH General Contact GrafGalenStraße 17 59269 Beckum Send EMail2021年2月1日 The crusher closed side setting is infinitely adjustable within setting limits through the actuation of hydraulically controlled wedges and tension rod spring The wedge assembly is fully contained within the crusher frame A hydraulic power pack, positioned close to the crusher, provides push button control Main shaftJaw Crushers JW Series Terex2016年2月17日 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended Standard crushers, in the small and medium sizes, are customarily fitted with chillediron head and concaves for crushing Gyratory Crushers 911 Metallurgist2020年12月17日 In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle Crushing 101 – Different types of crushers for distinctive needs

.jpg)

Crushing Products Size and Shape What to Expect 911

2016年2月26日 In short, they eliminate much of the oldtime guess work in the preparation of the plant flowsheet CrusherSetting, ProductSize Using Crusher and Screen Charts and are of great value in the preparation of plant flowsheets, and in calculating vibrating screen capacities Their use in the latter connection will be discussed in the Crushing Screening Plant Assessment Example Capacities and Horsepower of Jaw Crushers (tons/hr) Typical Capacities of TwinRoll Crushers (tons/hr) have the needed capacity a jaw crusher like the Crusher Efficiency Calculations 911Metallurgist2016年3月10日 Short Head (Tertiary) Cone Crusher (Refer to Fig 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In)Crushing Plant Flowsheet DesignLayout 911 Metallurgist2023年2月24日 Estimated Cost of Setting Up a Stone Crusher Plant The cost of setting up a stone crusher plant varies depending on the factors mentioned above Generally, the estimated cost to set up a stone Stone Crusher Plant Setup Cost: Factors,

.png)

Selecting the right crusher for your operations Quarry

2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)2016年4月14日 equipment is selected to meet or exceed the capacities Design criteria can be calculated from a simple spreadsheet as shown in Table 2 can all affect crusher plant design Construction costs are generally much greater at high altitudes, in cold climates and at remote sites To improve the economics of such locations, modular and pre Crushing Plant Design and Layout Considerations 911 2019年7月9日 CRUSHER CAPACITIES IN TONS [TONNES] 125 275 150 275 100 275 200 150 275 200 200 200 230 230 220 230 250 250/300 250 250 300/350 220 210 210 210 190 LIPPMANN HEAVYDUTY JAW CRUSHER DIMENSIONS Lippmann Milwaukee, Inc 3271 East Van Norman Avenue Cudahy, WI 531100586 (800) 6480486 • (414) 7442565HEAVYDUTY JAW CRUSHERS MidStates AggA welldesigned plant layout balances the capital versus operating cost over mine life Buildings, infrastructure, and major equipment items, represent the major cost elements of a crushing plant a welldesigned project flowsheet specifies tonnage requirements and the equipment is selected to meet or exceed the capacities REQUEST MORE Crushing Plant Design and Layout Yeco Machinery

Cone crusher basics in 4 minutes SRP

Sandvik CH cone crusher The open side and closed As the feed is crushed, it falls and exits the crusher through the space at the bottom The eccentric gyration of the mantle means that at any moment this space is narrowest at one point, and widest at the opposite point The widest distance is known as the open side setting (OSS) and the Check the aggregate crushing plant process flow chart below 200tph mobile crusher plant for aggregates 150TPH Mobile Sand Making Plant For Quartz Sand Production Configurations: APG3895W (vibrating feeder) + APJ6090E The mobile crushing plant capacities range from 45tph to 500tph tire typeAggregate Crusher Plant in The Philippines 10 ~ 1000 tph2022年7月1日 Palm Kernel Crusher Plant Operation kernel, followed by screwpressing whereas plants with larger capacities (50500 t day1) usually pretreat the kernel completely before screwpressing as described Mechanical palm kernel crushing process flow chart Figure 5 Mechanical screw press for palm kernel oil extractionPalm Kernel Crusher Plant Operation and Economic

石灰石矿石样本

--矿石磨粉机背衬

--水渣的化学成分含量标准

--花岗岩生产线建设项目

--年产10万吨超细矿渣粉的立磨设备

--pl

--HCM系列超细磨粉机

--矿石制粉厂开办矿石制粉厂开办矿石制粉厂开办

--碳酸钙粉磨厂微粉磨碳酸钙粉磨厂微粉磨碳酸钙粉磨厂微粉磨

--山地维克重晶石磨粉机

--低耗热烧结砖轮窑

--探矿权保证的账务处理

--水泥磨淘汰产业政策

--煤矿常见岩石价格等级煤矿常见岩石价格等级煤矿常见岩石价格等级

--菱镁矿椰壳活性炭制粉机械矿石磨粉机

--工业磨粉机厂家安全管理规定

--沥青石灰石压实系数

--红土镍制粉加工机械

--矿渣水泥成套设备工艺流程

--煤矸石的发热值

--矿石制粉冼精品砂粉设备

--大型超微粉机器

--鞭炮时点燃了草垛可以用泥土沙子扑灭吗

--来自中国的矿石磨粉机白垩加工设备

--雷蒙机吧

--干拌沙浆设备

--方解石摆式磨粉机

--剥片机工作原理

--注册煤矿承包挖煤公司

--一破鳄破和二破预粉磨砂粉同出立磨的区配原则

--