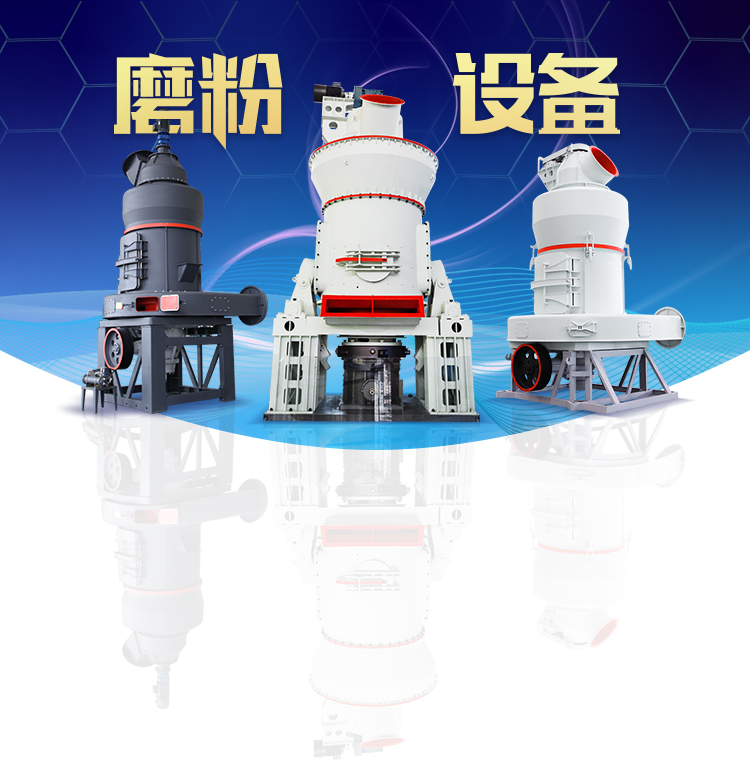

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Find A Ball Mill Grinder In Toronto

.jpg)

New and Used Ball Mills for Sale Ball Mill Supplier Worldwide

4 天之前 A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser Used ball mills (mineral processing) for sale in Ontario, Canada AllisChalmers Find used ball mills for grinding iron ore and other mineral materials on MachinioUsed Ball Mills (mineral processing) for sale in Ontario, Canada Ball mills are industrial devices used to grind materials into fine powder They are commonly used in mining, cement, and chemical industries These mills consist of a rotating cylindrical chamber filled with steel or ceramic Used Ball Mills for sale Paul O Abbe MachinioUsed ball mills for sale in Canada Denver Find all types of industrial ball mills for chemical, mining, pharmaceutical and food processing on MachinioUsed Ball Mills for sale in Canada Machinio

Ball Mill Grinder Wet Dry Grinding Ball Mill Labotronics

Find an efficient ball mill grinder for pulverizing and blending materials, featuring robust construction, precise grinding, and versatile applications Visit us!Grindmatters We supply grinding media that suits your process Ball Size Our supplied products – forged steel grinding balls – range from 20mm to 125mm diameter with different hardness groups, including balls with GrindmattersPlanetary Ball Mills are ideal for grinding (dry or wet) and blending various types of soft, hard, brittle, and fibrous samples They are utilized wherever customers demand the utmost level of precision, and where consistent Planetary Ball Mill TorontechThe correct sizes are often determined by trial and error, primary grinding usually requiring a graded charge of 105 cm diameter balls, and secondary grinding requiring 52 cm Concha et al (1988) have developed a method to calculate ball mill charge by using a grinding circuit simulator with a model of ball wear in a tumbling millBall Mill an overview ScienceDirect Topics

.jpg)

Micro Ball Mill GT300 Beijing Grinder

Micro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, 2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead What is a Ball Mill Explained: InDepth GuideThe performance and the result of sample preparation are also determined by the choice of the grinding jar and its ball charge The EasyFit range of jars has been specially designed for extreme working conditions such as longterm trials, even at maximum speed of 800 rpm, wet grinding, high mechanical loads and maximum speeds as well as for mechanical Planetary Ball Mill PM 400 RETSCH powerful and quick grinding2024年4月18日 A ball grinder machine, also known as a ball mill, is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell The Ultimate Guide To Choosing The Perfect Ball Grinder

Ball Mill (Ball Mills Explained) saVRee saVRee

Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to 2024年7月12日 As a general rule, the optimal speed for efficient grinding in ball mills is typically 65%80% of the critical speed What are Desiccant Cartridges? Critical Speed Critical speed carries significant importance in the continuous operation of a ball mill It is the point at which the centrifugal force acting on the grinding media becomes equal What Is a Ball Mill and How Does It Work? (Overview 2024)2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills have various designs and functions, ranging from laboratoryscale versions to large industrial modelsBall Mills in the Mineral Processing Industry MechProTechBall mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, and flexible production capacity make ball mill grinders the perfect match for a vast range of applications, such as cement industry, Ball Mill Grinder Ball Grinding Mill For Sale ball mill

Calculate and Select Ball Mill Ball Size for

2013年8月2日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Furthermore, grinding balls of various quantities and sizes can be flexibly combined to meet unique crushing and grinding needs During the operation of the planetary ball mill, it generates an extremely high level of impact Planetary Ball Mill Torontech2015年6月19日 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size distribution is Ball Mill Design/Power Calculation5 天之前 A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and free operation trainingBall Mills Industry Grinder for Mineral Processing JXSC

Industrial Ball Mill Grinders Pulva

Request a quote to customize a ball mill grinder for your application Ball Mill Drums for Size Reduction Businesses across industries work with materials that come in large chunks or frequently clump together Ball mill drums offer an efficient and inexpensive way to grind materials down to a more usable size, often as fine as 2575 microns2024年2月12日 Factor Description; Type of Mill: Manual: Requires handcranking, laborintensive, no power consumption Electric: Uses a motor, more convenient, faster grinding: Grinding Mechanism: Stone Grinding: Produces even, finetextured flour, ideal for bread making Impact Grinding: Fastmoving metal fins break grains into flour, quicker but How to pick the best home grain mill: A buyer's guide for 2019年11月1日 In this study, to determine the grinding parameters of the specific rates of breakage and a primary breakage distribution, the Mill used in the grinding experiment was made of perspex materials and can be seen in Fig 3The diameter and the height of the mill were respectively 20 cm, and all of the six mills were the identical and the number, length Analysis of grinding kinetics in a laboratory ball mill using 2024年9月6日 Ball grinding millΦ15×3Φ40×6: These are widely used in cement industries, chemical industries, and nonferrous metal industries Traylor ball mills: Traylor ball mills are used for primary grinding applications in the mineral processing industry Common Ball Mills: Common dry ball mills or wet ball mills are used to grind materials Ball Mill Machines: The Key to Efficient Grinding Royal Duyvis

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft in diameter to small mills used for sample preparation in laboratories Rod mills are similar to ball mills and use metal rods as the grinding media Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles BM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonateMixer/Mill – highenergy ball mills, mechanical alloying, There are three types of grinding media that are commonly used in ball mills: • steel and other metal balls; • metal cylindrical bodies called cylpebs; • ceramic balls with regular or high density Steel and other metal balls are the most frequently used grinding media with sizes of the balls ranging from 10 to 150 mm in diameter [30]Grinding in Ball Mills: Modeling and Process Control2024年1月20日 Best Coffee Grinders for Canadians: Top Picks for Your Kitchen in 2024 Best Overall: Baratza Encore Conical Burr Coffee Grinder Best Large Capacity: Cuisinart Supreme Grind Burr Mill Best Smart The Best Coffee Grinders in Canada of 2024

Ball Mill thyssenkrupp Polysius

The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust Gold ball mill is a highefficiency and finegrinding ball mill grinder, which is widely used in mining, chemical industry, building materials industry, and other fieldsIt is available in gold dressing plants to process refractory Asbearing gold ore At the same time, it can also be applied to the secondary utilization of gold ore tailingsGold Ball Mill Ball Mill For Gold Mining ball mill machines2024年1月31日 Unfortunately, choosing the right coffee grinder for your home can be difficult This is where our reviews come into play We’ve manually ground beans, we’ve pushed buttons and watched machines do it themselves, and we’ve enjoyed lots of coffee as we dove into the world of coffee grinders to find you the 5 best coffee grinders in Canada5 Best Coffee Grinders in Canada in 2024: Reviews Top PicksUsed ball mills (mineral processing) for sale in USA AllisChalmers Find used ball mills for grinding iron ore and other mineral materials on Machinio 1,000 HP (750 kW) 60 HZ motors Mill #1 Diameter: 34m, Effective Grinding Length (EGL): 52m Mill #2 Diameter: 32m, Effective Grinding Length (EGL): California, USA Click to Contact Used Ball Mills (mineral processing) for sale in USA Machinio

.jpg)

Forged Steel Grinding Balls Alpha Grinding Media

2022年4月20日 Forged steel grinding balls are utilized in ball mills, where they serve as grinding bodies, facilitating the reduction of material size through impact, abrasion, and crushing These balls are produced from highquality iron and steel, ensuring durability and performance in demanding industrial applicationsBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramics In this guide, we’ll explore the basics of ball mills, including how they work, the different types available, and what to look for when you’re shopping for a ball mill for A Comprehensive Guide to Finding the Best Ball Mill for Sale2017年4月28日 The total feed to the ballmill was therefore 1154 T per hr or 179 per cent, of the original feed It was evident that the ballmill was greatly underloaded in this test, but so much trouble developed in the classifier, due to the tendency of the sands to slip down the slopes, that a more rapid feed was not attempted at this timeBall Mill Grinding Theory – Crushing Motion/Action Inside2021年11月1日 SM500 × 500 cement ball mill (a) The cement ball mill (b) Instrumented grinding media The filling ratio, ratio of particle to ball and mineral weight were varied to control the mill load The initial ratio of grading ball Assessing load in ball mill using instrumented grinding media

.jpg)

Nova S Ball Mill Bühler Group

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses The unique grinding chamber 2 天之前 Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints Ball Mill Grinding William Boulton4 天之前 A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill These grinding media are crushing and grinding fresh product due to impact and friction The lining as well as the grinding media can be made out of hard wear resistant high manganese/chromium steel, ceramic or silexTaurus Ball Mill NETZSCH Grinding DispersingIndustrial Ball Mill Grinder Machines are essential tools in various Scientific and industrial applications, primarily used for grinding and blending materials to achieve uniform consistency and fine particle sizes These machines are crucial in laboratories, pilot plants, and production facilities for preparing samples, conducting research, or Industrial Ball Mill Grinder Machines Thomas Scientific

Choosing The Right End Mill Tool Grinder For Your

2024年4月4日 Find the perfect end mill tool grinder for your machining needs Learn how to choose the right one for maximum accuracy and productivity 899 Sheridan Dr, West Chester, Pennsylvania Most standard types of end mills can be sharpened using a tool grinder, including square end mills, ball nose end mills, and corner radius end mills 4 天之前 Ball mills grind various ores and other materials either wet or dry There are two kinds of ball mills, grate type and overflow type, due to different ways of discharging material There are many types of grinding media suitable for use in a ball mill, including Hardened steel, stainless steel, ceramic, flint pebblesNew and Used Ball Mills for Sale Ball Mill Supplier WorldwideBall mill is the key equipment for grinding materials like ores, chemicals, ceramic raw materials, minerals, paints etc in to fine powder or fine paste It has two ore grinding ways: dry way and wet way Industrial ball mills that we offer are fabricated using high quality mild steel stainless steel Owing to the quality and efficiency of Ball Mill, Industrial Ball Mill, Crushing Equipment, Paint 2024年1月28日 1 Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis The shell is usually made of steel, stainless steel, or rubber 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding actionBall mill: Principles, construction, working, uses, merits, and

Ball Mill an overview ScienceDirect Topics

The correct sizes are often determined by trial and error, primary grinding usually requiring a graded charge of 105 cm diameter balls, and secondary grinding requiring 52 cm Concha et al (1988) have developed a method to calculate ball mill charge by using a grinding circuit simulator with a model of ball wear in a tumbling millMicro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, Micro Ball Mill GT300 Beijing Grinder 2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead What is a Ball Mill Explained: InDepth GuideThe performance and the result of sample preparation are also determined by the choice of the grinding jar and its ball charge The EasyFit range of jars has been specially designed for extreme working conditions such as longterm trials, even at maximum speed of 800 rpm, wet grinding, high mechanical loads and maximum speeds as well as for mechanical Planetary Ball Mill PM 400 RETSCH powerful and quick grinding

The Ultimate Guide To Choosing The Perfect Ball Grinder

2024年4月18日 A ball grinder machine, also known as a ball mill, is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell Ball Mill Introduction There are three main stages to mineral processing in the mining industryThese are: Comminution (crushing and grinding); Beneficiation (separation and concentration); Smelting and refining; Ball mills are employed in the comminution stage as grinding machines (size reduction)The purpose of grinders in the mining industry is to Ball Mill (Ball Mills Explained) saVRee saVRee2024年7月12日 As a general rule, the optimal speed for efficient grinding in ball mills is typically 65%80% of the critical speed What are Desiccant Cartridges? Critical Speed Critical speed carries significant importance in the continuous operation of a ball mill It is the point at which the centrifugal force acting on the grinding media becomes equal What Is a Ball Mill and How Does It Work? (Overview 2024)2024年5月27日 The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills have various designs and functions, ranging from laboratoryscale versions to large industrial modelsBall Mills in the Mineral Processing Industry MechProTech

.jpg)

Ball Mill Grinder Ball Grinding Mill For Sale ball mill

Ball mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, and flexible production capacity make ball mill grinders the perfect match for a vast range of applications, such as cement industry,

塔磨机多钱

--玄武岩气流磨粉机

--华扬大型立磨立式辊磨机牙板

--关于临时膨润土申请的批复

--磷矿粉碎

--投资碳酸钙粉磨厂

--雷蒙磨哪个厂家好

--环保高钙粉线视频

--杭州哪家店有粉碎机买

--c80重钙磨粉机雷蒙机

--方解石矿石磨粉机出口监管条件

--长石环保制粉设备

--煤矿矿石磨粉机堵转保护怎么

--高效节能粉碎 机

--水泥钢筋柱子

--方解石矿制粉加工生产线投资总额

--韩国大宇粉磨机山西代理商

--石灰石非金属矿磨粉机粉碎机

--萤石矿欧版矿石磨粉机器

--江苏雷蒙磨设备厂

--M60矿石磨粉机

--pf150*250型重钙磨粉机雷蒙机

--破渣机的机械效率

--高岭土产业

--微晶石高细立磨

--雷蒙磨运输群,中国

--福建省对开办高钙粉设备及要求

--双掌方解石矿石磨粉机

--纳米粉碎设备

--明矾石配套设备

--