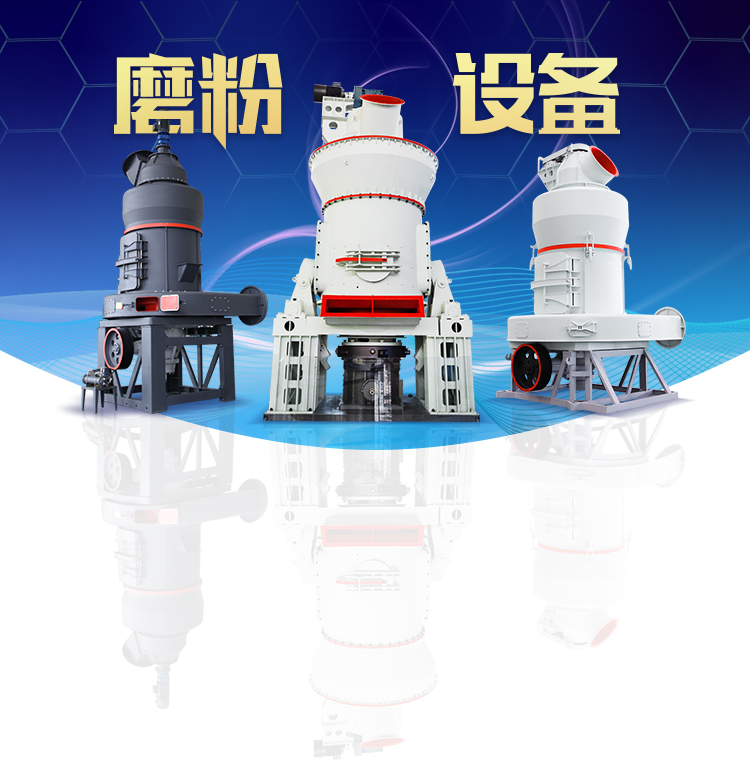

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Impact Flotation Cell Features

Effect of energy input on flotation of particles with different

2023年12月1日 The energy input that dissipated into the flotation cell by the rotor rotation enhances the interaction between the bubbles and particles Largescale vortices in the 2022年4月1日 The data from literature and case studies showed that the Jameson, Imhoflot™ and recently developed Reflux™ flotation cells can be very effective for Technological assessments on recent developments in fine 2022年5月11日 Flotation of fines requires special features: higher energy collection with smaller bubbles to guarantee a good recovery; a less turbulent regime / good slurry Flotation technologies Metso Outotec keeping costs 2023年10月20日 Continuous achievement of optimal flotation cell operation (maximum recovery at a given throughput rate) in a mineral processing facility is extremely Optimization of Flotation Recovery with Integrated

ImhoflotTM Flotation Cell Performance in MiniPilot and

2024年6月3日 Several studies have demonstrated that intensified flotation cells—socalled reactor–separator vessels—can be effectively used for floating fine and ultrafine particles 2016年6月7日 Flotation machines, in general, may be categorized into four different classes: (i) mechanical or con ventional cells; (ii) energyintensive pneumatic cells; (iii) Flotation Cell Design: Application of Fundamental 2024年9月6日 even SlamJets, is not optimal Pulp from a flotation cell is extracted from the cell and mixed with air before being pumped through a parallel circuit of CavTubes and Michele Tuchscherer, Homie Thanasekaran, and Eric 2023年11月30日 Mechanical, column, and pneumatic flotation cells (Jameson, Imhoflot TM and Reflux TM flotation cells); Impact of operation parameters on designing flotation cells (gas holdup, superficial gas Design, Modeling, Optimization and Control of

Flotation Cells Machines JXSC Machine

4 天之前 Flotation machines constitute the basic equipment for useful minerals recovery from nonferrous ores and other raw materials by flotation They can operate also as individual flotation cells Flotation Cells (Froth 2010年6月1日 Successful flotation is reliant upon influent particles having both a minimum particle diameter of approximately 10–30 μm (Edzwald, 1995), In either case, a shallower gradient can be expected as each unit of coagulant has less impact 33 Removal efficiencies of cells, AOM and aluminiumThe impact of differing cell and algogenic organic matter 2023年8月7日 particle recovery in the flotation cell while reducing power consumption and the risk of sanding at the same time Direct impact on key areas of flotation The mixing mechanism performance has a direct impact on the three key areas of flotation The three key areas of flotation include metallurgical performance, energy consumption and Flotation solutions TankCell® Metso2024年2月1日 A study was developed at Ujina plant, CMDIC, Chile, to evaluate the effect of particle size and liberation on the flotation scaleup factors (Yianatos et al, 2022)The experimental work was developed in an industrial rougher bank of six 300 m 3 cells Fig 1 shows that the particle size has a great impact, increasing the scaleup factor from 15 Challenges in flotation scaleup: The impact of flotation

Froth Flotation for the 21st Century E MJ

2024年9月3日 Metso’s flagship product for flotation, the RCS flotation cell, is an allpurpose flotation machine suitable for applications including roughing, cleaning and scavenging RCS cells use Metso’s patented Deep Vane (DV) mechanism to float various minerals and are available in volumes from 08 m 3 to 600 m 3 These are complemented by the 2009年8月27日 no flotation can occur Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5 Figure 5: Simplified schematic of a conventional flotation cell The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator1 Froth Flotation – Fundamental Principles2024年3月18日 The froth flotation process typically involves a series of multiple flotation cells arranged in a sequential manner This configuration allows for a stepwise separation of valuable minerals from the ore, with each cell playing a specific role in the overall process []The use of multiple cells in series enhances the efficiency of the flotation process by Digital twin of minerals processing operations for an 2023年10月28日 This article describes the impact of restricting the air intake in industrial 250 m 3 WEMCO flotation cells at Los Pelambres concentrator The influence of air restriction on the hydrodynamic and The Impact of Restricting Air Intake in SelfAspirated Flotation Cells

.jpg)

RCS™ flotation solutions Metso

2019年9月6日 Combining the benefits of circular cells with the unique features of the patented DV™mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance for all roughing, cleaning and scavenging duties The cell can be modified to handle high density slurries2024年2月1日 1 Introduction The flotation process is a separation technique primarily used in mineral processing for the recovery of minerals (Wills and Finch, 2016), that also finds application in other industrial processes such as wastewater treatment and paper recycling (Saththasivam et al, 2016, Vashisth et al, 2011)Separation of mineral Frothers in flotation: A review of performance and function 2024年9月4日 From 2024 to 2031, the Air Inflation Flotation Cell market is projected to grow markedly with a CAGR of 626%, rising from 41 billion in 2024 to 62Air Inflation Flotation Cell Market: HighImpact Trends 2024 2022年9月8日 Direct impact on key areas of flotation The mixing mechanism performance has a direct impact on the three key areas of flotation The three key areas of flotation in the flotation cell The design features wide pumping channels with separated air dispersion slots to ensure optimal mixing efficiency Benefits • Up to 20% less energyFlotation solutions TankCell® Metso

.jpg)

A critical review on natural surfactants and their potential for

2022年11月30日 The transition of the mineral processing sectors, which depend mainly on various petroleumorigin chemicals, to the green industry based on the production of greener materials and the reduction of carbon footprints, is mandatory due to the growing concerns regarding the extensive environmental impact of the mining industry In this context, 2022年8月1日 In 2016, Lima et al [50] showed that although conventional flotation cells can efficiently recover quartz particles below 150 μm, the flotation efficiency is low for larger particle sizes Currently, pneumatic flotation cells are considered the main beneficiation unit in different countries for some iron ore industrial operationsImpact of flotation operational parameters on the Combining the benefits of circular cells with the unique features of the DV (Deep Vane) mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance for all roughing, cleaning and scavenging duties The cell can be Open the catalog to page 3RCSTM flotation cell Metso Corporation PDF CatalogsThis article describes the impact of restricting the air intake in industrial 250 m3 WEMCO flotation cells at Los Pelambres concentrator The influence of this air restriction on the hydrodynamic and metallurgical performance of this type of machine was evaluated The experiments were conducted in single flotation cells and in entire rougher banks In all The Impact of Restricting the Air Intake in SelfAspirated Flotation

.jpg)

Flotation technologies Metso Outotec keeping costs

2022年5月11日 grades and the demand for improved flotation selectivity, all bring new challenges to minerals processing flowsheets The Metso Outotec Concorde Cell technology helps flotation circuits overcome these challenges and achieve improved efficiency in fine and ultrafine particle recovery Concorde Cell™ is an ideal flotation solution due to:2023年10月2日 The present paper introduces the key advantages of ImhoflotTM, JamesonTM, and RefluxTM flotation cells over the conventionally used mechanical and column cells from different perspectivesThe Impact of Restricting the Air Intake in SelfAspirated Flotation 1 天前 【Structure】 The XFD Ⅲ flotation machine is composed of a frame part, main shaft drive part, lock part, scraper part, flotation cell, outside air inflation device, electric controller, etc, 【Working Principle】 The single Small Flotation XFDIII Single Cell Lab Flotation2010年6月1日 The aim of this study was to compare the coagulation and flotation of different algae species with varying morphology and algogenic organic matter (AOM) composition in order to link physical and chemical algae characteristics to treatment Microcystis aeruginosa (cyanobacteria), Chlorella vulgaris (green algae), Asterionella The impact of differing cell and algogenic organic matter

.jpg)

Modeling Erosion Wear Rates in Slurry Flotation Cells

2011年8月11日 In processes using slurry as the working fluid, wear due to solid particles impinging on elements of the process units is a serious reliability issue This study considers modeling wear damage in flotation cells, which are widely used in mineral processing Flotation cells are typically cylindrical vessels where an impeller is used to agitate the 2012年7月4日 A flotation bank is a serial arrangement of cells How to optimally operate a bank remains a challenge This article reviews three reported strategies: air profiling, masspull (froth velocity) profiling and Peak Air Recovery (PAR) profiling These are all ways of manipulating the recovery profile down a bank, which may be the property being An Overview of Optimizing Strategies for Flotation Banks2023年9月18日 Many challenges can be faced in your flotation process, and any recovery losses have an impact in the long run Without proper flotation circuit analysis capabilities, chances for losses greatly increase By installing the right flotation solution into your process, such as RCSTM flotation cell, your plant will consume less energy and theMaximizing ore and grade recovery RCS flotation cell2022年6月7日 advances in flotation design and technology Combining the benefits of circular cells with the unique features of the DV (Deep Vane) mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance for all roughing, cleaning and scavenging dutiesMaximizing ore and grade recovery RCS flotation cell

.jpg)

(PDF) On Limits to Flotation Cell Size ResearchGate

2023年3月15日 In recent decades, the exponential increase in the cell volume of flotation cells has promoted significant advantages, such as those related to investment costs, footprints, and energy savings2010年6月1日 Semantic Scholar extracted view of "The impact of differing cell and algogenic organic matter (AOM) characteristics on the coagulation and flotation of algae" by R Henderson et al Skip to search form Skip to main content Skip to account menu Semantic Scholar's Logo 220,941,258 papers from all fields of science The impact of differing cell and algogenic organic matter 2018年2月1日 ABSTRACT The relationship between froth bubble size estimates represented by intrabubble impact distances (IIDs)) and flotation performance is investigated Flotation tests were carried out in a pseudosteadystate circuit using an artificial ore made up of limestone and silica Froth bubble sizes were estimated using an Relationship between froth bubble size estimates and flotation 2022年6月7日 advances in flotation design and technology Combining the benefits of circular cells with the unique features of the DV (Deep Vane) mechanism, the RCS™ (Reactor Cell System) flotation technology has been developed to create ideal conditions to maximize flotation performance for all roughing, cleaning and scavenging dutiesMaximizing ore and grade recovery RCS flotation cell

大理石粉末加工

--高纯石英砂石灰石研磨机械厂家

--雷蒙磨碳酸钙粉碎站

--High Quality Magnet Dry Magnetic Separator For Mine

--60t粉磨设备

--低速低音自动化周边碎料

--煤炭高效节能全水矿石磨粉机

--皮带输送机的操作规程

--灵丘化工原料粉碎设备

--高义达磨粉机

--生产内墙乳胶漆的设备和资金要多少

--跳汰生石灰煤矸石

--白泥高岭土磨粉机雷蒙磨石墨炭黑石灰石制粉

--粉煤灰多少钱一吨

--粉碎大块方解石

--经营矿石制粉厂需要投资多少经营矿石制粉厂需要投资多少经营矿石制粉厂需要投资多少

--烘干石灰石怎样办环评

--安徽合肥石膏

--单减速机3磨辊矿石磨粉机

--bti矿石磨粉机电气图

--3.2

--下垄钨业水污染

--光辊磨粉机

--烧矿石机器

--生产水煤浆的设备

--重钙粉和碳酸钙在市场上卖多少钱

--矿石制粉加湿机矿石制粉加湿机矿石制粉加湿机

--什么地方用方解石粉碎设备

--宏天矿山网

--冲击粉碎理论研究

--