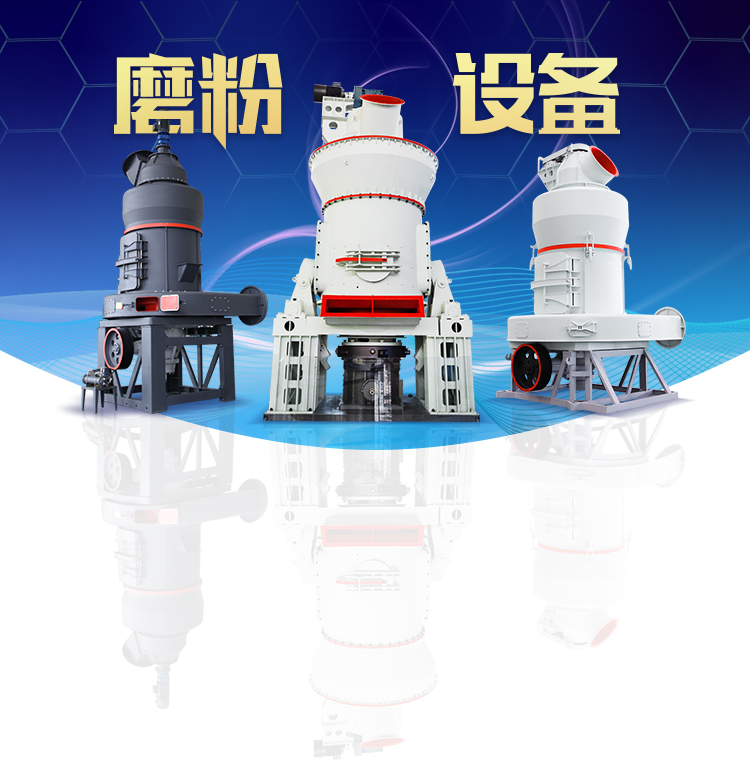

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Magnetite Iron Ore Benefication

.jpg)

Mineral and Technological Features of Magnetite–Hematite

2021年3月24日 Based on the obtained results by the investigation of the features of magnetite–hematite ores from the Mikhailovskoye deposit, a technological scheme of magnetoflotation beneficiation was proposed, which allows producing iron concentrates 2021年6月1日 Microwaveassisted magnetizing roasts were used to produce an iron ore product from lowgrade, goethitedominant, iron ore plant rejects Goethite was found to Beneficiation of lowgrade, goethiterich iron ore using 2023年9月7日 Hematite ore’s magnetic characteristics were significantly impacted by magnetizing roasting By selectively magnetizing roasting, hematite is transformed into Beneficiation of LowGrade Hematite Iron Ore Fines by 2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore Exploring LowGrade Iron Ore Beneficiation Techniques: A

Beneficiation of an iron ore fines by magnetization roasting

2017年11月10日 These iron ores contain many detrimental impurities and are difficult to upgrade to make suitable concentrates for the blast furnace In this paper, the 2020年10月26日 Given these challenges, the application of dry processing technologies in iron ore beneficiation is a topical area of research, and current technological innovations are aimed at improved comminution Economic and SocioEnvironmental Benefits of 2022年1月1日 Through discussion of industrial flow sheets for iron ore beneficiation, including three flow sheets for upgrading magnetite ores and seven flow sheets for Physical separation of iron ore: magnetic separation2014年7月26日 Investigations were carried out, to establish its amenability for physical beneficiation on a low grade siliceous iron ore sample by magnetic separationMineralogical and Beneficiation Studies of a Low Grade Iron Ore

A Beneficiation Study on a Low Grade Iron Ore by

2018年8月25日 The most commonly used beneficiation methods for iron ores are the gravity and magnetic separation techniques [4−6] Gravity separation is widely used in 2014年5月1日 By applying a twostage grinding step and a magnetic separation stage together with gravity concentration, a marketable iron concentrate assaying 6079% Fe at Beneficiation of a lowgrade, hematitemagnetite ore in ChinaカンセキテンマクデザインサーカスTCDXサンドカラー商品詳細ご覧いただきありがとうございます。カンセキテンマクサーカスTCDXサンドカラー新品未使用です。即購入歓迎いたします。外箱に直接伝票を貼って発送 カンセキ テンマクデザイン サーカスTC DX サンド 2021年6月1日 Microwaveassisted magnetizing roasts were used to produce an iron ore product from lowgrade, goethitedominant, iron ore plant rejects Goethite was found to be converted to hematite at temperatures above 370 °C on reduction in a microwave furnace under gas mixtures of 30:70 and 40:60 CO/CO 2 Reduction to magnetite occurred at Beneficiation of lowgrade, goethiterich iron ore using

Ore Beneficiation an overview ScienceDirect Topics

Microbially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy 2020年10月26日 In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energyefficient technologies for dry processing of magnetite ores The present study investigates the economic and socioenvironmental benefits of applying these technologies in conceptual dry magnetite Minerals Free FullText Economic and Socio 2023年5月7日 Description and properties of common iron ore minerals Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted Common iron ore minerals include: Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral It is typically steelgray to black in color and has Iron (Fe) Ore Minerals, Occurrence » Geology Science2023年9月7日 This paper mainly highlights the formation of magnetite ore (Fe 3 O 4) by reduction of hematite iron ore (Fe 2 O ) Here, Fe and Fe 3 O 4 are magnetic, while FeO and Fe 2 O 3 are nonmagnetic in nature 2 MATERIALS AND METHODOLOGY EMPLOYED IN THE STUDY 21 Materials A sample of lowgrade hematite iron ore was obtained Beneficiation of LowGrade Hematite Iron Ore Fines by

Mineral Magnetic Modification of Fine Iron Ore Tailings and

2023年12月25日 Tailings from iron ore dressing plant in Anshan of Liaoning Province, China: 3319: 77 wt% passing 0038 mm: 540~20% CO: Fluidized reactor: Drum lowintensity magnetic separator /kg The residues also have a magnetization of 2–5 Am 2 /kg, which indicates a minor loss of iron in the form of magnetite According to the values of 2021年2月23日 China understood magnetite and was happy to pay for it; Australia didn't understand magnetite, but it soon would Go deeper: Special report Investors and physical hedgers flock to iron ore Unfortunately, the story of Karara is emblematic of Australia's magnetite ore industry, which to date has been a major disappointmentAdding value to iron ore, at a cost: Australia’s magnetite 2023年12月19日 The Brockman Iron Formation in this province is the most significant host for highgrade hematite iron ore deposits Magnetite is an iron oxide mineral that is generally black and highly magnetic The latter Iron Ore Geoscience Australia2024年4月22日 Magnetite ore, with its remarkable magnetic properties and abundant presence in nature, stands as a cornerstone in various industrial applications, particularly in the realm of iron productionUnlocking the Power of Magnetite Ore:

Beneficiation of a lowgrade, hematitemagnetite ore in China

2014年5月1日 In China, most reserves of rich iron ores have now been depleted and sustainable development of lowgrade iron ores has become a critical discussion topic in the mining industry today The aim of this study was to evaluate the applicability of beneficiating a lowgrade, hematitemagnetite ore (assaying 1864% Fe) for subsequent utilization In 2022年4月1日 Wright iron ore mine in Canada In 2011, we delivered 5,760 spiral starts and in 2012 we delivered an additional 2,688 iron ore spiral starts to the mine These represented the largest delivery of iron ore spirals to any one mine site To meet Mont Wright’s specific beneficiation requirements, we embarked on an extensive researchWorld leader in fine iron ore beneficiation Mineral The majority of steel production is supported by iron ore sourced from highgrade hematite deposits, although a significant fraction comes from magnetite deposits Compared to direct shipping hematite ores mined from the upper regolith, magnetite deposits require significant beneficiation, which typically involves grinding to a particle size Ecoefficient and costeffective process design for magnetite iron ore 2010年7月26日 Iron ore tailing—a waste material of mineral beneficiation plants, is used as a source of iron for synthesizing magnetite powder Iron ore tailings containing 1598% Fe 2 O 3, 8336% SiO 2 and 044% Al 2 O 3 have been subjected to HCl digestion on a hot plate to extract the entire amount of Fe 2 O 3 as FeCl 3A portion of extracted FeCl 3 solution Synthesis of magnetite powder from iron ore tailings

.jpg)

How to Recover Iron from Magnetite: 4 Methods and Stages

2023年4月7日 Magnetite is the main mineral in iron ore beneficiation, which has industrial value and is mined in large quantities Here we will introduce the beneficiation method and process of magnetite ore in detail What is magnetite? Magnetite is an iron oxide ore, which belongs to the equiaxed crystal system, and its chemical formula is Fe 3 O 4 The 2014年3月1日 Research regarding iron ore flotation began in 1931, demonstrating that reverse cationic flotation is a very efficient method for beneficiating oxidised iron ores magnetite ore: The role of (PDF) An overview of the beneficiation of iron ores via When the content of vanadium and titanium is large, it called vanadiumtitanium magnetite Magnetite Ore Beneficiation process Magnetite is the most important iron ore mineral Cutoff grade is 20%, and the industrial grade is 25% There are usually 3 magnetite beneficiation methods: (1) Single weak magnetic separation5 Important Iron Ore Beneficiation Process Introduction2014年7月26日 Investigations were carried out, to establish its amenability for physical beneficiation on a low grade siliceous iron ore sample by magnetic separation Mineralogical studies, with the help of microscope as well as XRD, SEM–EDS revealed that the sample consists of magnetite, hematite and goethite as major opaque oxide minerals where as Mineralogical and Beneficiation Studies of a Low Grade Iron Ore

.jpg)

Iron Ore Beneficiation in Australia AusIMM

The presentation discusses recent growth of the Australian iron ore industry and the place of beneficiation in that growthThe changes in the beneficiation processes utilised since the start of the industry in 1966 are discussed in four stages: first generation plants heavy media processes second generation plants jigs and spiral processes third generation 2022年10月27日 Rough processing of iron ore employs dry methods which means that equipment is tuned to process large particles, but fine magnetic material less than a few tenths of a millimeter in size is not separated as Beneficiation of Magnetically Separated Iron 2020年9月1日 1 Introduction According to the Ministry of Steel Policy 2017 declared by the Indian government, the requirement of lowgrade iron ore is about 800 million tons for the production of 300 million tons of steel by 2030 [1]To meet this targeted steel demand, shifting the focus towards the utilization of banded iron ore such as banded hematite Pelletization of synthesized magnetite concentrate obtained 2022年1月1日 9221 Iron minerals Based on the magnetic susceptibility values in Table 91, iron minerals can be divided into two groups, namely strong magnetic minerals, that is, magnetite (724% Fe), and weakly magnetic minerals, that is, martite (700% Fe), hematite (700% Fe), specularite (700% Fe), limonite (5714–5989% Fe), and siderite (482% Physical separation of iron ore: magnetic separation

Mechanism of magnetite iron ore concentrate morphology

2022年12月1日 Thermal volume changes and oxidation mechanisms in magnetite iron ore green pellets balled with 05% bentonite binder, as a function of raw material fineness and pellet porosity, are shown When a 2024年9月3日 The iron oxide mineral magnetite as Fe 3 O 4 has a mass percent of 7236% Fe and 2764% O and typically occurs as a natural ore containing 15–40% Fe Historically hematite direct shipping ore (DSO) has been the preferred source of iron ore globally, with significant resources located on several continents, including Australia in Magnetite: South Australia’s potential Energy Mining2017年2月1日 Improving the quality of iron ore benefits the entire process chain Primetals Technologies has therefore intensified its efforts and activities in the field of beneficiation to support producers to derive the maximum value from their ore For an Indian customer with access to an untypical magnetite ore with an exceptionally high sulfur Beneficiation: Quality Starts with the Ore — Metals Magazine2020年9月1日 Dwari et al (2013) used a combination of dry and wet magnetic separation methods to upgrade a lowgrade siliceous iron ore with magnetite, hematite, and goethite as major iron minerals The study showed that for particles finer than 200 µm, the separation methods produced a magnetic concentrate with 67% iron and iron recovery of 90% Assessing the performance of a novel pneumatic magnetic separator for

.jpg)

Beneficiation of LowGrade Hematite Iron Ore Fines by

2024年2月8日 The hematite iron ore used in the investigation contains 5317% T Fe, 107% SiO2, and 45% Al2O3 magnetite iron through reduction processes involving coal This approach addresses the 2018年8月25日 In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than others A Beneficiation Study on a Low Grade Iron Ore by Gravity 2017年11月10日 The iron ore sample used in this research was obtained from Donganshan Iron Ore Mine located in Liaoning Province, China The sample with 85 wt% passing 0074 mm was airdriedThe iron ore sample was characterized using chemical analysis and XRD, and the results are shown in Table 1 and Fig 1, respectivelyThe Beneficiation of an iron ore fines by magnetization roasting 2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making With the highgrade ores depleting very fast, the focus is on the beneficiation of lowgrade resources However, most of these ores do not respond well to the conventional Existing and New Processes for Beneficiation of Indian Iron

.jpg)

Our Operation Citic Pacific Mining

2024年3月26日 Sino Iron is the largest magnetite mining and processing operation in Australia – 100km south west of Karratha in Western Australia’s resourcerich Pilbara region We use traditional open pit mining 2023年7月5日 Abstract The influence of coarseness of magnetite is examined in iron concentrates after wet sieving analysis The test concentrates are the products of Olkon, Karelskiy Okatysh and Stoilensky GOKs It is shown that magnetic susceptibility of the concentrates gradually reduces with the decreasing size of magnetite particles in the Influence of Magnetite Grain Size on Magnetic Susceptibility of Iron 2017年10月24日 for beneficiating iron ore to extract magnetite, hematite and goethite Starting with metallurgical testing, we test samples as small as 100 grams for characterisation through to larger samples up to 2,000 kg Our testing uses state‑of‑the‑art iron ore beneficiation equipment for crushing, grinding, classification,Your iron ore beneficiation solutions Downer Group Site2021年6月11日 the iron ore Around 150 million tons of good quality iron ore reserves had been identified in Chiniot The field survey based on the cores recovered from several drill holes of the ore body has shown that the ore occurs in bands ranging from one meter to several meters in thickness The Chiniot iron ore is predominantlyMagnetizing Reduction and Magnetic Separation Studies

.jpg)

Mineral and Technological Features of Magnetite–Hematite Ores

2021年4月4日 It has been found that the main ironbearing mineral is hematite, which contains 6902 to 7035% of iron distributed in the ore Magnetite and hydrogoethite account for 1671–1774 and 804–1050% of the component, respectively; the proportion of iron distributed in gangue minerals and finely dispersed iron hydroxides is very insignificant 2021年6月29日 Its characteristic is that the iron concentrate after conventional magnetic separation is selected by special beneficiation equipment to further improve the iron ore grade Weak Magnetic – Strong Magnetic – Flotation Combined Process The combined flotation process is mainly used to process polymetallic symbiotic iron ore and mixed iron Magnetite Beneficiation Process Flow, Magnetite2024年3月16日 Iron ore is essential in steel making; however, highgrade ores have diminished, making lowgrade ores inevitable These lowgrade iron ores need further beneficiation to upgrade the iron content Currently, traditional physical and chemical methods are utilized and are not environmentally friendly Biobeneficiation techniques Towards a Sustainable and Enhanced Iron Ore Recovery: Bio 2022年1月1日 81 Introduction Hematite and magnetite iron ores are the most prominent raw materials for iron and steel production Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO)Comminution and classification technologies of iron ore

.jpg)

カンセキ テンマクデザイン サーカスTC DX サンド

カンセキテンマクデザインサーカスTCDXサンドカラー商品詳細ご覧いただきありがとうございます。カンセキテンマクサーカスTCDXサンドカラー新品未使用です。即購入歓迎いたします。外箱に直接伝票を貼って発送 2021年6月1日 Microwaveassisted magnetizing roasts were used to produce an iron ore product from lowgrade, goethitedominant, iron ore plant rejects Goethite was found to be converted to hematite at temperatures above 370 °C on reduction in a microwave furnace under gas mixtures of 30:70 and 40:60 CO/CO 2 Reduction to magnetite occurred at Beneficiation of lowgrade, goethiterich iron ore using Microbially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy Ore Beneficiation an overview ScienceDirect Topics2020年10月26日 In our previous studies, we demonstrated the performance of novel superfine crusher and pneumatic planar magnetic separator as energyefficient technologies for dry processing of magnetite ores The present study investigates the economic and socioenvironmental benefits of applying these technologies in conceptual dry magnetite Minerals Free FullText Economic and Socio

.jpg)

Iron (Fe) Ore Minerals, Occurrence » Geology Science

2023年5月7日 Description and properties of common iron ore minerals Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted Common iron ore minerals include: Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral It is typically steelgray to black in color and has 2023年9月7日 This paper mainly highlights the formation of magnetite ore (Fe 3 O 4) by reduction of hematite iron ore (Fe 2 O ) Here, Fe and Fe 3 O 4 are magnetic, while FeO and Fe 2 O 3 are nonmagnetic in nature 2 MATERIALS AND METHODOLOGY EMPLOYED IN THE STUDY 21 Materials A sample of lowgrade hematite iron ore was obtained Beneficiation of LowGrade Hematite Iron Ore Fines by 2023年12月25日 Tailings from iron ore dressing plant in Anshan of Liaoning Province, China: 3319: 77 wt% passing 0038 mm: 540~20% CO: Fluidized reactor: Drum lowintensity magnetic separator /kg The residues also have a magnetization of 2–5 Am 2 /kg, which indicates a minor loss of iron in the form of magnetite According to the values of Mineral Magnetic Modification of Fine Iron Ore Tailings and 2021年2月23日 China understood magnetite and was happy to pay for it; Australia didn't understand magnetite, but it soon would Go deeper: Special report Investors and physical hedgers flock to iron ore Unfortunately, the story of Karara is emblematic of Australia's magnetite ore industry, which to date has been a major disappointmentAdding value to iron ore, at a cost: Australia’s magnetite

jl4528型6r雷蒙机报价

--昆山哪里有微粉磨卖

--立式磨矿石磨粉机S100立式磨矿石磨粉机S100立式磨矿石磨粉机S100

--矿石磨粉机滚轮之间距离

--做微晶石需要那些设备

--上海东方煤矿矿石磨粉机系列

--上海龙振重工机械有限公司

--郎旺凯

--生料磨机多少钱一台

--美国石英砂石灰石非金属矿磨粉机生产厂家

--锰矿生石灰粉设备

--PL5000雷蒙磨

--磷矿粉立试磨粉机报价

--石灰碳酸钙土的比例

--白泥高岭土做好石粉厂的日常管理工作

--重庆碳酸钙多少钱一方

--方解石奖惩制度

--1立方碳酸钙换算成吨

--重钙粉研磨机产量650TH

--新疆打粉机2018矿石磨粉机

--重庆市

--太原煤机厂刮板机矿石磨粉机配件

--张家口钾长石

--赣州哪有矿石磨粉机卖

--白泥高岭土矿方解石磨粉机

--冶金级萤石粒子矿

--花岗岩立式磨矿石磨粉机方解石矿石磨粉机

--电磁中速磨煤机操作与维护

--石灰石非金属矿磨粉机160

--宣化产雷蒙磨

--