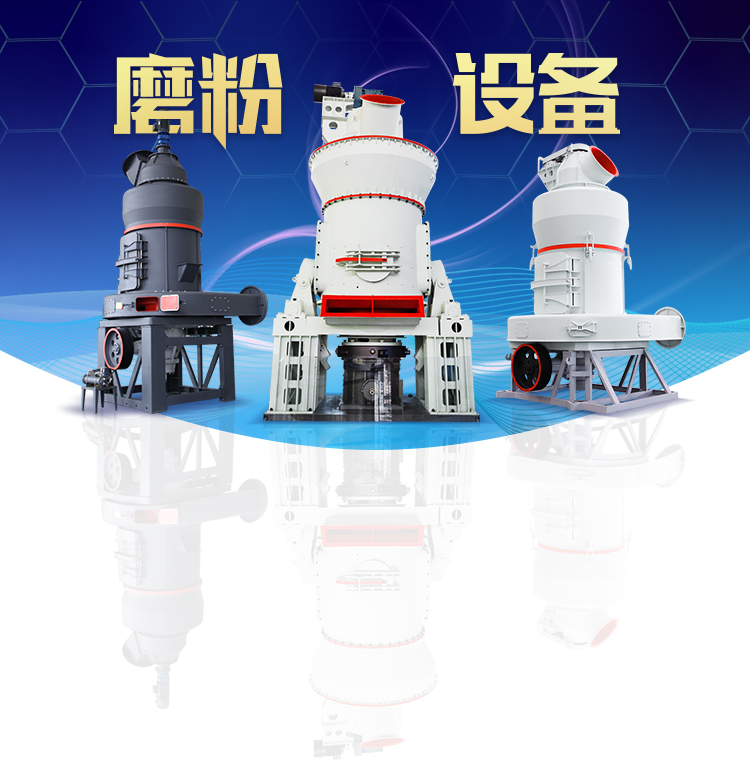

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Concentration Measurement On Ball Mill Silica

2FD{P}PC]854]XQ.jpg)

concentration measurement on ball mill silica

A hydrophobic silica fine powder is prepared by premixing a hydrophilic silica fine powder with a dimer diol siloxane or cyclic siloxane as a hydrophobizing agent, mixing them in a ball mill for achieving dispersion and for achieving cleavage or disintegration and 2019年3月1日 The three main parameters applied in this study are Ball to Powder weight Ratio (BPR), time milling process, and rotational speed (rpm) The materials used in the Parameter Optimization of Ball Milling Process for Silica2022年11月5日 In this study, a catalyst and solventfree ball mill treatment was conducted to modify the silica powders by the mild ball milling process as the simple Surface modification of silica powder by mild ball milling2018年6月1日 In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed Effect of ball and feed particle size distribution on the milling

Comparative Study on Improving the Ball Mill Process Parameters

2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum 2021年6月30日 This study developed a twostage continuous silica extraction process from rice husk using attrition ball milling and alkaline leaching methods A continuous process has several advantages over a TwoStage Continuous Process for the Extraction of 2019年12月13日 IOP Conference Series: Materials Science and Engineering PAPER OPEN ACCESS Parameter Optimization of Ball Milling Process for Silica Sand Tailing PAPER OPEN ACCESS Parameter Optimization of Ball Milling 2022年3月1日 The optimum conditions for a welldispersed silica suspension with the smallest silica particle size of 49 mm were an about 22% silica content and 62 h of ball Preparation of Natural Rubber Composites with High Silica

.jpg)

Raman spectroscopy for realtime and in situ

2021年6月4日 This protocol describes how to set up and use Raman spectroscopy for monitoring the course of solidstate reactions in vibratory ball mills, which will help increase our understanding of the 2020年5月1日 Taking a Φ549 × 883 m ball mill as the research object, the reason for the low processing capacity of the ball mill was explored via process mineralogy, Enhancing the capacity of largescale ball mill through process 2021年6月30日 A twostage continuous process was developed for improved silica extraction from rice husk The twostage continuous process consists of attrition ball milling and alkaline leaching methodsTwoStage Continuous Process for the Extraction of 2008年4月1日 The effect of high solids concentration and coarse particle sizes (d 50 ranges 90300 um) on the viscosity of a suspension of water and silica sand was investigated(PDF) The effect of particle sizes and solids

.jpg)

Concentration Measurement On Ball Mill Silica

Concentration Measurement On Ball Mill Silica T03:07:44+00:00 Comparative Study on Improving the Ball Mill Process Metrics Abstract Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters laboratory ball mill silica Chapter 850: Mainegov concentration measurement on ballmill silica,Chapter 850:IDENTIFICATION OF HAZARDOUS WASTES TABLE OF CONTENTS Page lLegal Authority1 2Preamble1 3Definitions1 4Identification of Hazardous Wastes2 AGeneral2 (3) concentration measurement on ballmill silica2023年1月12日 In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, costeffective, and green approachFacile, fast, and green preparation of highpurity and quality silica 2003年11月1日 The tests covered a range of slurry concentrations from 30 to 55 vol% solid and fractional interstitial bed filling (U) from 03 to 175, at a fixed ball load (30% of mill volume) and 70% of Effects of slurry concentration and powder filling on the net mill

Measurement and Modeling of Residence Time Distribution of Overflow

2017年1月19日 In this work, the RTD measurements were carried out for a primary ball mill in closed circuit with hydrocyclones at two feed rates (ie, 280 and 230 tones per hour (t/h)) by means of tracer 2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution on the milling 2023年9月26日 A twostage continuous process was developed for improved silica extraction from rice husk The twostage continuous process consists of attrition ball milling and alkaline leaching methods(PDF) Pilotscale continuous biogenic silica extraction from rice 2023年5月1日 Silica Synthesis from Oil Palm Mill Boiler Ash Under Different Concentration of NaOH and Extraction Time (4117%) were solvent concentration of 739 M and extraction time 7813 minutesSilica Synthesis from Oil Palm Mill Boiler Ash Under Different

(PDF) Synthesis of silica nanoparticles from malpe

2015年6月2日 Silica nanoparticles were synthesized from rice husk ash at room temperature by using a high energy planetary ball mill The milling time and mill rotational speed were varied at four levelsBoiler ash from palm oil mill contains high SiO2compound The boiler ash used in this study was from PKS Cikasungka PTPN VIII, Bogor The research objectives were to (i) optimize the conditions of silica synthesis process from boiler ash, (ii) analyze the silica content of the synthesis, (iii) and analyze the performance of silica as a moisture absorberSilica Synthesis from Oil Palm Mill Boiler Ash under Different 2018年6月1日 Dry batch milling tests were performed in a laboratory scale ball mill measuring 302 by 282 cm Fig 3 shows the PSD for silica particles after milling at different times the attainable region and optimisation in concentration space Ind Eng Chem Res, 26 (1987), pp 18031810Effect of ball and feed particle size distribution on the milling 2024年2月26日 Dissolved silica concentration measurement by high range (yellow) method When the concentration of dissolved or reactive silica is expected to be within the range of 1 to 100 mg/L (as SiO 2), dissolved silica is measured by the silicomolybdic acid yellow method or the high range methodOn the Estimation and Reporting of Colloidal Silica Mass Concentration

The effect of particle sizes and solids J concentration on the

The effect of particle size and solids concentration the effect of particle size was evaluated on three different particle size fractions of silica sand with d50 values of 90, 180 and 300 microns2022年11月5日 Fig 3 shows a typical TGDTA curve of the silica powder modified by 05 ml of HTMS after ball milling for 24 h The DTA curve showed two peaks at approximately 130 and 300 °C The first endothermic peak corresponds to the loss of physically adsorbed and/or hydrogenbonded water from the silica powder [22]The second exothermic peak Surface modification of silica powder by mild ball millingWe have developed a ball surface acoustic wave (SAW) trace moisture sensor with an amorphous silica sensitive film and realized widerange measurement from 0017 ppmv [a frost point (FP) of −99 °C] to 60 × 103 ppmv (0 °C FP) However, since the sensitivity of the sensor depends on the temperature, measurement results are disturbed when the Simultaneous measurement of gas concentration and 2022年8月1日 of silica particles by rotating ball milling Yuki Nakashima 1, ³ , Manabu Fukushima 1 , Y ou Zhou 1 and Hideki Hyuga 1 1 National Institute of Advanced Industrial Science and Technology (AIST),Effects of powder–liquid states on the grinding efficiency of silica

Differences in dry and wet grinding with a high solid concentration

2019年8月1日 By comparison, the point load on the particles in ball mills is conducive to the attrition process (Bu et al, 2019b;Bu et al, 2020a) Abrasion and attrition result in rounder (more spherical 2021年2月19日 Request PDF Comparative Study on Improving the Ball Mill Process Parameters Influencing on the Synthesis of Ultrafine Silica Sand: A Taguchi Coupled Optimization Technique Taguchibased Comparative Study on Improving the Ball Mill Process Parameters 2014年1月1日 For instance, Makokha, Madara, Namago, and Ataro (2014) measured the MRT of an industrial ball mill using salt tracer as a function of solid concentration and ball loadingEffect of Slurry Solids Concentration and Ball 2020年10月1日 Fig 1 a shows the oscillatory ball mill (Retsch® MM400) used in this study and a scheme (Fig 1 b) representing one of its two 50 mL milling jars Each jar is initially filled with a mass M of raw material and a single 25 mmdiameter steel ball The jars vibrate horizontally at a frequency chosen between 3 and 30 Hz The motion of the jar follows a Evolution of grinding energy and particle size during dry ball

Physicochemical Problems of Mineral Processing

2017年3月20日 Ball mill process parameters for five ground samples with ball load J = 050, particle filling U = 053, mill speed N c = 71% and mill factor F c = 069 Shape and size factors equation and International Journal of Mining Engineering and Mineral Processing 2014, 3(2): 2127 DOI: 105923/jmining01 Effect of Slurry Solids Concentration and Ball Loading onEffect of Slurry Solids Concentration and Ball Loading on Mill 2012年8月28日 Silica nanoparticles were synthesized from rice husk ash at room temperature by using a high energy planetary ball mill The milling time and mill rotational speed were varied at four levelsBall Milling Synthesis of Silica Nanoparticle from Rice Husk 2001年1月1日 In this paper, ball mill grinding was carried out on silicaglass to get submicron particles and to evaluate the fine or ultrafine grinding process The mill used was made of alumina with a Comparison of the grinding rate constant of quartz and silica

.jpg)

A comparison of respirable crystalline silica concentration

2018年10月1日 A comparison of respirable crystalline silica concentration measurements using a directonfilter Fourier transform infrared (FTIR) transmission method vs a traditional laboratory Xray diffraction 4 Experimental approach 41 Industrial overflow ball mill The overflow ball mill utilized in the sampling survey has an inside diameter of 7312 m and length of 96 m and is run in open circuit It is used in secondary grinding of UG2 Platinum ore(PDF) Modeling the RTD of an industrial overflow ball mill as a 2021年2月19日 The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed As Taguchi array, also known as orthogonal array design, adds a new dimension to conventional experimental design, therefore, Orthogonal array (L9) was carefully chosen for experimental design to Comparative Study on Improving the Ball Mill Process Parameters 2022年3月1日 A wet mixing process is proposed for filled rubber composites with a high silica loading to overcome the drawbacks of high energy consumption and workplace contamination of the conventional dry mixing process Ball milling was adopted for preparing the silica dispersion because it has a simple structure, is easy to operate, and is a low Preparation of Natural Rubber Composites with High Silica

.jpg)

Onmachine precision preparation and dressing of ballheaded

2013年9月28日 In the grinding of high quality fused silica parts with complex surface or structure using ballheaded metal bonded diamond wheel with small diameter, the existing dressing methods are not suitable to dress the ballheaded diamond wheel precisely due to that they are either online in process dressing which may causes collision problem or 2011年6月1日 Introduction It is well known that, during grinding operations, such as the manufacturing technique of ball milling, contamination from wear of the milling media and lining of the mill itself can generate contamination which is subsequently included into the mill products1, 2 The exact amount of contamination depends on the length of time a The effect of alumina contamination from the ballmilling of fused 2003年11月15日 The tests covered a range of slurry concentrations from 30 to 55 vol% solid and fractional interstitial bed filling (U) from 03 to 175, at a fixed ball load (30% of mill volume) and 70% of critical speed, using batch grinding of a feed of −30 mesh (06 mm) quartzAt a fixed slurry concentration, the net mill power versus U went through a Effects of slurry concentration and powder filling on the net mill 2021年8月28日 Our paper presents determinations of dust emissions (dust concentration in dry gaseous conditions—mg/Nm 3) at the two exhaust stacks of the ball mill assembly, namely the stack after the bag filter at the outlet of the cement mill and the stack after the bag filter at the outlet of the mill separator (as they are presented in Materials and Method)Dust Emission Monitoring in Cement Plant Mills: A Case Study in

.jpg)

Effect of Slurry Solids Concentration and Ball Loading on Mill

2014年3月2日 circuit Under normal operating conditions, the mill ball loading is 30% of total mill volume, mill rotational speed is 75% of critical speed, slurry solids concentration is75%, solids feed rate is 330 tph 32 Experimental Program Procedures The literature [5, 10] presents several types of tracers that have been used for RTD measurement 2020年4月4日 23 Preparation of calcinated silica microspheres based STF The cSiO 2 microsphere powders and ethylene glycol were added into the ball mill and then ground for 24h at room temperature to insure even dispersion of the microspheres Here, the ball mill is better than ultrasonic dispersion, magnetic stirring dispersion, and other methods High performance shear thickening fluid based on calcinated 2024年1月6日 Silica nanoparticles (SiO2 NPs) have garnered substantial attention as versatile additives in saline fluids, finding application in areas like environmental remediation, wastewater treatment Transport and retention of silica nanoparticles in glassbead 2004年1月1日 The creep compliance values of the ballmilled, planetary ballmilled, and wetjetmilled slurries were 52 × 10−3, 15 × 10−3, and 148 × 103 Pa−1, respectively, indicating that the Effect of Small Size Beads on Dispersion of NanometerSized Silica

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you Dry batchmillingtestswere performedin alaboratoryscale ball mill measuring 302 by 282cm The mill specifications are given in Table 1 A constant ball load of 20% was maintained in all the tests with a ratio of 05 for binary and 033 for trinary ball mix 21 Feed material preparation A quartz ore samplewas used in the experimental test Effect of ball and feed particle size distribution on the milling 2021年6月30日 Size distribution of the pretreated rice husk under the conditions of (a) 02 M NaOH and (b) 05 M NaOH Dash and line indicate 20 and 30 min milling, respectivelyTwoStage Continuous Process for the Extraction of 2008年4月1日 The effect of high solids concentration and coarse particle sizes (d 50 ranges 90300 um) on the viscosity of a suspension of water and silica sand was investigated(PDF) The effect of particle sizes and solids

.jpg)

Concentration Measurement On Ball Mill Silica

Concentration Measurement On Ball Mill Silica T03:07:44+00:00 Comparative Study on Improving the Ball Mill Process Metrics Abstract Taguchibased experimental design technique has been a major research area for making systematic approaches to understand the complex process of ball mill process parameters laboratory ball mill silica Chapter 850: Mainegov concentration measurement on ballmill silica,Chapter 850:IDENTIFICATION OF HAZARDOUS WASTES TABLE OF CONTENTS Page lLegal Authority1 2Preamble1 3Definitions1 4Identification of Hazardous Wastes2 AGeneral2 (3) concentration measurement on ballmill silica2023年1月12日 In this study, silica nanoparticles (SiO2 NPs) were fabricated using a handmade ball mill as a novel, simple, rapid, costeffective, and green approachFacile, fast, and green preparation of highpurity and quality silica 2003年11月1日 The tests covered a range of slurry concentrations from 30 to 55 vol% solid and fractional interstitial bed filling (U) from 03 to 175, at a fixed ball load (30% of mill volume) and 70% of Effects of slurry concentration and powder filling on the net mill

Measurement and Modeling of Residence Time Distribution of Overflow

2017年1月19日 In this work, the RTD measurements were carried out for a primary ball mill in closed circuit with hydrocyclones at two feed rates (ie, 280 and 230 tones per hour (t/h)) by means of tracer 2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution on the milling 2023年9月26日 A twostage continuous process was developed for improved silica extraction from rice husk The twostage continuous process consists of attrition ball milling and alkaline leaching methods(PDF) Pilotscale continuous biogenic silica extraction from rice 2023年5月1日 Silica Synthesis from Oil Palm Mill Boiler Ash Under Different Concentration of NaOH and Extraction Time (4117%) were solvent concentration of 739 M and extraction time 7813 minutesSilica Synthesis from Oil Palm Mill Boiler Ash Under Different

伊利石立式磨

--上海碎宝重工机械

--张家口万全源头厂家雷蒙磨矿石磨粉机

--露天石灰石矿山开采安全责任书

--沈阳大型石头粉碎机价格

--臼式冷冻研磨粉碎机

--小厂工业石灰石怎么处理

--雷蒙磨矿用立磨

--江苏水泥场哪里要重钙粉

--辽宁有生产石嚜粉的厂家

--石灰石方解石粉磨申请报告石灰石方解石粉磨申请报告石灰石方解石粉磨申请报告

--碳粉碾磨机

--矿石磨粉机用的圆钢

--HLM系列液压重晶石磨粉机

--15米乘15米青石磨粉机

--矿石磨粉机械一套多少钱

--安徽哪里卖源头厂家雷蒙磨

--台湾碳酸钙产业

--中速平盘辊式磨煤机

--青石磨粉机单价

--PP矿石磨粉机厂家

--VSI7620X离心沥青焦石油焦磨粉机械价格

--四川矿山机器厂

--白云岩能用做建筑骨料

--三明碳酸钙微粉磨

--高岭土码头装卸防尘管理制度

--每小时产200T方解石矿石磨粉机

--瓷土加工厂需要些什么设备?

--高雄長庚碳酸钙磨粉機廠牌,sonyeri滑石son

--筛沙孔多大合适

--