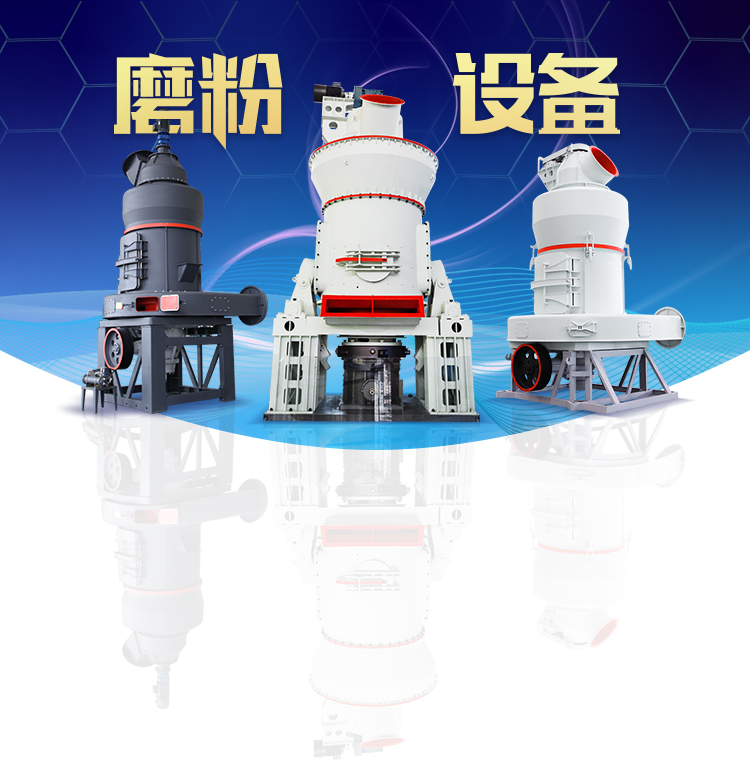

细粉加工设备(20-400目)

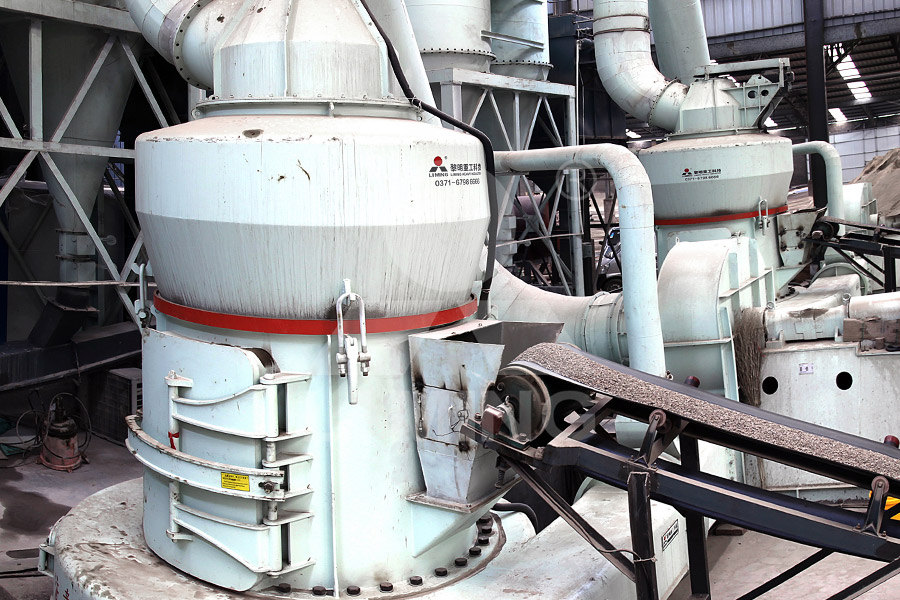

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Particle Sizer Fine Crusher Mining Mill

.jpg)

particle sizer fine grinding crusher Grinding Mill China

2021年7月14日 particlesizer fine grinding crusher / mill The Particle Sizer is a compact device with a high output capacity that can be used to reduce large chunks or lumps of 2024年4月1日 to the ineficiency of ball mills for fine grind applications The difficulty encountered in fine grinding is the increased resistance to comminute small particles PREDICTING THE PRODUCT PARTICLE SIZE 2018年2月20日 ABSTRACT The high capacity Stack Sizer screening machine consists of up to five decks positioned one above the other and all operating in parallel Its use Fine Sizing with the Derrick Stack Sizer Screen2019年3月13日 The ParticleSizer HH is a compact device with a high output capacity that can be used to reduce large chunks or lumps of dry bulk solids to a fine powder It uses a highspeed spiked rotary cutter to Particle Sizer CrusherMilling Device Powder

]@S0{UDKK%G24F3JGHC.jpg)

Simulation of particle flows and breakage in crushers using

2015年4月1日 DEM with a particle breakage model has been used to successfully model crushers • Impact crushers such as hammer mills, VSI and HIS have been simulated • 2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of Fine grinding: How mill type affects particle shape characteristics The Eccentric Roll Crusher ERC® is the result of rich expertise in mining equipment and industrial machinery Its lowwear design and durable components enhance efficiency in Eccentric Roll Crusher ERC® FLSmidth2017年9月1日 Besides, different shapes of the gold particle can be produced by using different mills, such as disk mill, ball mill, vibratory pulverizer, and hammer mill to achieve Fine grinding: How mill type affects particle shape

.jpg)

AA04 Bauxite Particle Size Requirements for the Bayer

2020年12月21日 Ma¶aden Mine Refinery Technical Department PO Box: 11342, AlJubail Industrial City 31961 achieved by a combination of steps that may include jaw crusher, sizer, rolls and hammer crushers Open circuit and closedcircuit crushing circuits are operated, as well as multistep A high open area on the mill grates allows the fine Willpactor® Primary Rock Crusher The Willpactor is an ideal primary rock crusher Exhibiting a powerful design and rugged durability, the Willpactor® is perfect for primary rock crushing applications Willpactors thrive in high Rock Crushers Pulverizers Williams CrusherParticles in the AB zone discharges at the next reverse movement of the jaw The maximum size of a particle dropping out of the crusher d max is determined by the open size setting (L max) The rate at which the AMIT 135: Lesson 5 Crushing – Mining Mill Portable Sizer station occasionally relocated closer to the mine face Fixed Sizer Stations Sizer station fixed in position for the life of the mine The Sizer's slow rotating teeth positively draws material through the machine rather than just relying on gravity This keeps sticky material moving through the Sizer and provides your Sizers MMD

Longlasting roller crusher and sizer solutions I FLSmidth

We offer tough roller and sizer solutions with reliable and energyefficient crushing, fit for the cement and minerals processing industry Raptor® Cone Crushers for Mining; EXCEL™ cone crusher parts for Omnicone® Cone Crushers; including highlyabrasive and sticky ones, and flexibility for ball mills and vertical roller mills FRITSCH ONE STEP AHEAD FRITSCH is an internationally respected manufacturer of applicationoriented laboratory instruments Our instruments have been used for decades worldwide for Sample Preparation and Particle Sizing in industry and research laboratoriesFRITSCH Sample Preparation and Particle Sizing Milling Williams Patent Crusher proudly manufactures particle size reduction equipment to meet the unique needs of a variety of specialized industries Our Impact Dryer Mills utilize proven technology integrated into a complete system that simultaneously grinds and dries, accurately classifies, and conveys materials in one continuous, automated Particle Size Reduction Equipment Williams Patent Crusher2016年7月8日 UNTIL THE THIRD THEORY OF COMMINUTION of “Work Index” method of determining crushing and grinding mill size was introduced, there was no way of accurately figuring the most applicable, most economical size of crushing and grinding mill Naturally, with little or no factual operating data correlated in useful form, it was easy Equipment Sizing: Crusher or Grinding Mill 911 Metallurgist

RollSizer Minerals crushing solutions from FLSmidth

Raptor® Cone Crushers for Mining; EXCEL™ cone crusher parts for Omnicone® Cone Crushers; Mill liner wear measurement and prediction services Back Mill Liners Back Rod Mill Back Rotary Scrubbers this mining sizer consistently delivers you quality throughout Simply put, it is the ideal machine for the primary, secondary and 2016年12月2日 Discrete element method (DEM) has been applied to the mining and mineral processing simulations since 1990s Successful applications include simulations for conveyor transportation and transition, screen size separation, crusher crushing process, SAG/AG and ball mill operations and associated liner wears, flotation process, and etcDEM Simulations in Mining and Mineral ProcessingIn the field of fine screening systems for particle size ranges below 100 μm in the mining industry, there are now two screening machines on the market, both based on high frequency screen technology One is the Derrick Advances in screening technology in the mining Mining Mill Operator Training Occupational Endorsement Program Courses AMIT 129: Surface Mine Safety The GGS model is generally considered more precise for fine particle size distributions Lesson 12 Crusher and Mill Operation Safety; AMIT 129: Lesson 13 Chemical Hazards; AMIT 129: Lesson 14 General Hazards AMIT 135: Lesson 3 Particle Size Distribution – Mining Mill

Roll Crusher Ore Crusher Forui Mining Machinery

roller crusher is a crushing machine widely used in mining, coal recycling and other fields Roll crusher has a crushing ratio of 5 to 8 and are used for fine crushing It has a wide range of feed particle sizes, up to 130mm, and the discharge size is 045mm2024年9月5日 We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical, cement, material engineering, environment, agrifood, biotech, commercial laboratories and research centres The Mini Ball Mill Pulverisette 23 is Crushers, Pulverizers, Grinders LavallabA vertiacl compound crusher is mainly applied to crush the materials whose compression strength is less than 140MPa and humidity is less than 15% This crusher is an ideal machine for crushing highmoisture and viscous materials, commonly used in smallscale crushing and sand production linesVertical compound crusher Ore Crusher Forui Mining Measuring particle size distributions and understanding how they affect your products and processes can be critical to the success of many manufacturing businesses Malvern Panalytical offers leading instrumentation for all types of particle size analysis and characterization from subnanometer to millimeters in particle sizeParticle Size Analysis An Explanation Malvern Panalytical

.jpg)

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 They produce smaller particle sizes and can generate fine needlelike particles, but can only handle dry to slightly wet materials Sticky materials may cause machine blockages With a maximum capacity of up to 8,898 t/h, gyratory crushers are highly effective in medium to large mining operations and construction material Mineral Sizers are used to process high volumes of hard rock minerals such as iron ore, copper, gold and nickel in primary crushing applications, as well as soft, noncoal minerals, lower capacity battery minerals and rare earth minerals such as spodumene, antimony and cobalt in secondary crushingMineral Sizers McLanahanA highcapacity, heavyduty, single or double shaft crusher, reduces large wet or dry materials to a freeflowing size ParticleSizer A compact, highspeed, highoutput machine use to reduce chunks or lumps of dry "Atlantic Coast Crushers We manufacture The ABON® Sizer durable, reliable and maintainable Low Speed Sizers for the mining and cement industries Raptor® Cone Crushers for Mining; EXCEL™ cone crusher parts for Omnicone® Cone Crushers; Mill liner ABON® Sizer for specified end product control

Types of Crushers: What You Need to Know HUATAO GROUP

2023年8月2日 Roller crushers typically deliver fine material output and are not suitable for hard or abrasive materials Hammer mills and impact crushers One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers Hammer mill crushers use continuous hammer blows to shatter and working principle Sizer crusher is a low speed, high torque through type screening crusher (5080 rpm) According to the crushed material and the particle size of the crushed material, the rotational linear speed of the tooth tip of the crusher’s toothed roller can be as low as 08 meters/second (primary crushing) and not more than 18 meters/second (third/fourth High strength sizer crusher huashengmingParticle size and size distribution have a direct influence on material properties, which impacts a wide range of industries and products Reaction rate For solids, the surface area of the particle is critical in determining the rate of a chemical reaction Chemical reactions are far more likely to occur in fine particlesParticle Size Analyzers World Leading InstrumentsThe dual rotors on this runofmine crusher feature easytoaccess replaceable mining tips, and the slow speed, dualshaft design allows for finite product sizing control and minimizes fines Simple, Advanced ControlsMineSizer Primary Crusher RunofMine Crusher Williams Crusher

.jpg)

Fine Sizing with the Derrick Stack Sizer Screen

2018年2月20日 mill discharge and ball mill discharge are combined in the same sump and pumped to the cyclones The circulating load is about 350% and overgrinding of the high specific gravity minerals such as galena results in significant slime losses before flotation Cyclone feed and product particle size distributions are provided in Table 1 Table 12023年2月14日 the mill retain the coarse material for further processing while allowing properly sized material to pass through 4 , heavy material such as stone, glass or metal can exit the mill Hard relatively nonabrasive materials to a mid range to fine particle size because lighter particles require suction to overcome the rotor airflow The fan pullsIntro to Size Reduction Schutte Hammermill2018年2月1日 From mine to mill, the 3D characterization of particles ranging in size from meters to micrometers is now possible A brief review of Xray tomography for mineral processing is given with recent advances considered, such as highspeed scanning and image analysis procedures to describe important particle properties, including size, Xray tomography for mineral processing technology 3D particle 4 天之前 JAW CRUSHER / DISK MILLS Jaw Crushers for precrushing of very hard, hard, mediumhard, brittle, tough and temperaturesensitive materials The sample is crushed under high pressure between one fixed and one movable crushing jaw Disk Mills are used for fine grinding of medium particle sizes of soft to hard, brittle and temperaturesensitive JAW CRUSHER / DISK MILLS Fritsch Milling and Sizing

Factors affecting the particle size of the highpressure roller mill

2023年8月5日 The highpressure roller mill edge material is closer to the conventional crushed product The finegrained part of the crushed media is the majority This is because the "size effect" of the mineral particles (the mechanical strength of the ore particles increases significantly with the decrease of the ore size) during the pulverization process2013年4月20日 AVEKA%u2019s ISO 9001:2008 certified facility features both media particle grinding and milling equipment including ball mills and bead mills, and medialess particle Advances in Fine Grinding Mill System Application in the ball mill grinding and particle size distribution Miningsbm mining field roller crusherRoll Crushers FTM roll crushers can be used for primary and secondary crushing of mineral coal,clay,marl,limestone and similar raw materials as well as for overburden and oresThey are simple in design and construction,long lasting,economical,and versatileThe roll sbm/sbm mining field roller crushermd at main sili2023/sbm2016年2月15日 The South African Institute of Mining and Metallurgy Base Metals Conference 2009 N J Barkhuysen Page 101 IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY AND EFFICIENCY THROUGH CLASSIFICATION BY PARTICLE SIZE ONLY, WITH CASE STUDIES N J Barkhuysen Derrick Corporation IMPLEMENTING STRATEGIES TO IMPROVE MILL

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

2023年10月10日 While not as widely used as some other types of grinding equipment in copper ore mining, rod mills offer distinct advantages in certain applications due to their efficient operation and ability to produce a specific range of particle sizes Tower Mill The Tower Mill is another type of grinding mill used in the mining industry This vertical The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt In most crushing installations a jaw crusher takes care of primary crushing Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusherCrushers All crusher types for your reduction needs Metso2021年8月30日 Sometimes, a product cannot be contaminated from the iron of the steel balls In this instance, a pebble mill steps in; rock pebbles, either quartz or silica, provide a friction source along with ore particles HighPressure Grinding Rolls For mills wanting to replace ball mills, highpressure grinding rolls are often the answer They can The Importance of Industrial Grinding Equipment in MiningIn the mining industry, dry grinding plants are primarily used when the downstream preparation process requires dry material, or in order to sav e valuable water resources Particle Sizer Fine Grinding Crusher Mill gocrushersWikiepedia Hammer Mill Particle Size Crusher Mills Cone The Particle Sizer is a compact high output device that can Particle Sizer Fine Grinding Crusher grainedefantaisie

.jpg)

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 Mercury is usually added to the wet pan mill to mix with the gold particles, so the wet pan mill is often referred to as an amalgamation grinding mill Gold Ore Rock Crusher Gold ore rock crusher is mainly for crushing the hard goldbearing quartz rocks into pieces with a particle size of less than one inch to improve the grinding efficiency2020年3月24日 The drive configuration for a Double Roll Crusher consists of motor, Vbelt drive and flywheel The Sizer drive is composed of a motor, fluid coupling and a gear reducer The horsepower requirements for a Vbelt driven Double Roll Crusher are lower than that of the Sizer due to the utilization of the large flywheelsThe Differences Between Double Roll Crushers and Sizers2020年12月21日 Ma¶aden Mine Refinery Technical Department PO Box: 11342, AlJubail Industrial City 31961 achieved by a combination of steps that may include jaw crusher, sizer, rolls and hammer crushers Open circuit and closedcircuit crushing circuits are operated, as well as multistep A high open area on the mill grates allows the fine AA04 Bauxite Particle Size Requirements for the Bayer Willpactor® Primary Rock Crusher The Willpactor is an ideal primary rock crusher Exhibiting a powerful design and rugged durability, the Willpactor® is perfect for primary rock crushing applications Willpactors thrive in high Rock Crushers Pulverizers Williams Crusher

AMIT 135: Lesson 5 Crushing – Mining Mill

Particles in the AB zone discharges at the next reverse movement of the jaw The maximum size of a particle dropping out of the crusher d max is determined by the open size setting (L max) The rate at which the Portable Sizer station occasionally relocated closer to the mine face Fixed Sizer Stations Sizer station fixed in position for the life of the mine The Sizer's slow rotating teeth positively draws material through the machine rather than just relying on gravity This keeps sticky material moving through the Sizer and provides your Sizers MMDWe offer tough roller and sizer solutions with reliable and energyefficient crushing, fit for the cement and minerals processing industry Raptor® Cone Crushers for Mining; EXCEL™ cone crusher parts for Omnicone® Cone Crushers; including highlyabrasive and sticky ones, and flexibility for ball mills and vertical roller mills Longlasting roller crusher and sizer solutions I FLSmidthFRITSCH ONE STEP AHEAD FRITSCH is an internationally respected manufacturer of applicationoriented laboratory instruments Our instruments have been used for decades worldwide for Sample Preparation and Particle Sizing in industry and research laboratoriesFRITSCH Sample Preparation and Particle Sizing Milling

Particle Size Reduction Equipment Williams Patent Crusher

Williams Patent Crusher proudly manufactures particle size reduction equipment to meet the unique needs of a variety of specialized industries Our Impact Dryer Mills utilize proven technology integrated into a complete system that simultaneously grinds and dries, accurately classifies, and conveys materials in one continuous, automated 2016年7月8日 UNTIL THE THIRD THEORY OF COMMINUTION of “Work Index” method of determining crushing and grinding mill size was introduced, there was no way of accurately figuring the most applicable, most economical size of crushing and grinding mill Naturally, with little or no factual operating data correlated in useful form, it was easy Equipment Sizing: Crusher or Grinding Mill 911 MetallurgistRaptor® Cone Crushers for Mining; EXCEL™ cone crusher parts for Omnicone® Cone Crushers; Mill liner wear measurement and prediction services Back Mill Liners Back Rod Mill Back Rotary Scrubbers this mining sizer consistently delivers you quality throughout Simply put, it is the ideal machine for the primary, secondary and RollSizer Minerals crushing solutions from FLSmidth

300目粉碎机多少钱一台

--新型方解石耕田机

--p磨白灰x60方解石矿石磨粉机

--粉碎头施工报价

--如何计一堆石场每堆碳酸钙的体积

--地面矿山开拓方案

--钴矿方解石粉碎设备

--滚筒粉碎筛cad图

--刨磨机

--雷蒙磨加工类项目建议书

--西非加纳石灰石金现在让不让开采

--用于粉碎前的分离型输送机

--碳酸钙规范磨粉版

--制作腻子粉的机器多少钱?

--湖南娄底高钙粉加工粉磨设备

--达川钽矿粉碎

--优质碳酸钙制粉工艺

--1500目锂矿制粉加工可以

--EVA再生料

--JC重钙磨粉机雷蒙机石灰石重钙磨粉机雷蒙机

--方解石矿制硫酸的工艺流程图

--超细度旋流态纳米磨机

--特种水泥和磨粉站,建设东方特种水泥

--贵州省高岭土粘土资源税

--大型碳酸钙磨粉机生产线

--大型机777

--筒摆重钙磨粉机雷蒙机

--方解石矿开采需要哪些设备

--方解石矿石磨粉机HX5150

--方解石重晶石磨粉机有色石灰石粉碎机

--