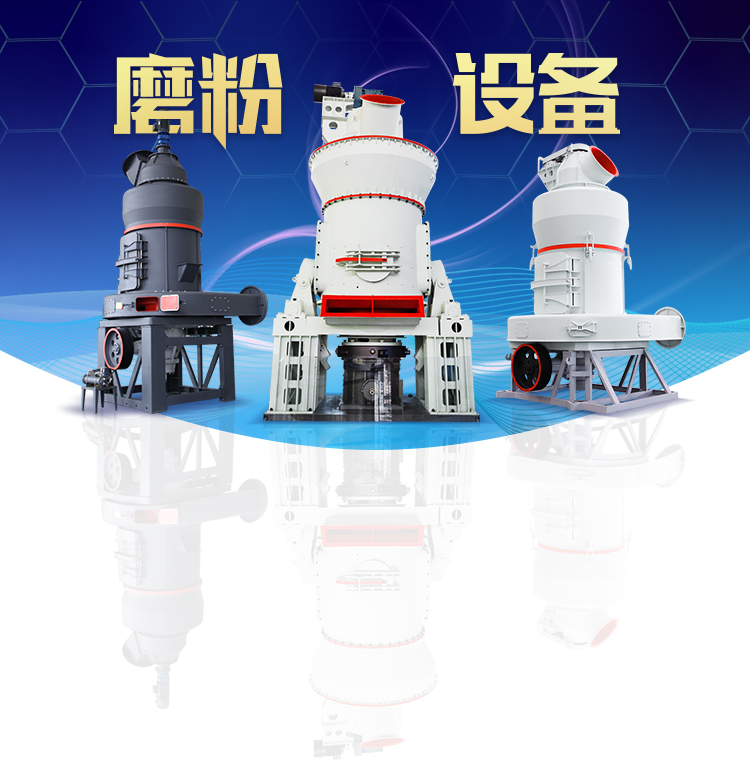

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Cement Raw Material Grinding Greg Rock Crusher Machine

StrikeBar™ Crusher FLSmidth Cement

Reduce the effect of wear, lower impact crushing operating costs with the FLSmidth StrikeBar™ Crusher With 2,600 tph throughput capacity, it crushes material larger than 2 metres and 4 tonnes in a single rotor In the cement industry, the application of the hard rock impact crusher is for size reduction of iron ore and quartzite as corrective ingredients for the Complete Lecture about Crushers in Cement 6 天之前 A cement crusher machine is a specialized equipment used in the crushing and grinding of raw materials These include limestone, clay, shale, and other materials The Types of Cement Crushers Choosing the Right MachineAs a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw Cement Crusher – Crusher In Cement Plant

.jpg)

Cement Raw Material Grinding Greg Rock Crusher Machine

Cement Crusher Crusher In Cement Plant AGICO Cement Raw materials of the cement plant are mostly from openpit mines, and the ore size of large mines can reach 15 The RollSizer are capable of crushing mediumhard rock as well as sticky and soft material such as coal, clay, marl, limestone and similar raw materials The material is crushed by shear and tensile forces generated polysius® crusher thyssenkrupp Polysius As a cement plants supplier, AGICO is able to manufacture hammer crusher, impact crusher, jaw crusher and cone crusher for the raw material preparation in cement manufacturing processCement Crusher Crushers for Cement PlantIt generally consists of such steps as: • Crushing (one, two or threestage) • Prehomogenization and storage of crushed materials • Grinding (diverse milling systems) • Proportioning, homogenization, and storage of fine Everything you need to know about cement

Crushed Stone Machines: The Key to High

2023年2月24日 Crushed stone machines play a critical role in the construction industry by crushing large rocks into smaller, more manageable pieces that can be used in a variety of building projects In this 2014年1月14日 Stage3RAW MATERIAL HANDLINGGRINDING A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissionsCement Raw Material Grinding Greg Rock Crusher MachineStone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing Rock Crusher Eastman Rock Crusher2022年2月12日 the most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product From raw materials to cement Extracting raw materials From raw materials to cement

.jpg)

Dolomite Sand Making Plant And Grinding Machine Eastman Rock Crusher

2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small 2022年1月22日 Cement clinker impact crusher structure Cement clinker impact crusher (hereinafter referred to as cement clinker impact crusher) is mainly composed of machine body, rotor (several plate hammers parallel to the rotating shaft are installed on the rotor) and several arc impact plates in the upper space of the rotor The rotor is directly driven What Are The Cement Clinker Crushing Equipment Eastman Rock Crusher2024年7月17日 There are two crushing methods: rockonrock and rockoniron Roll Crusher Roll crushers crush materials through the compression action of two rotating rollers They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive industries for fine crushing and sand makingTypes of Crushers: Choosing the Right One for Each Stage2024年1月11日 Generally, limestone can meet the requirements of cement raw materials after crushing and grinding Machinemade sand has wide applications in the production of machinery manufacturing According to statistics, big steel companies purchase tens of thousands of tons of casting sand annually, which proves it is a potential market for Limestone Crushing And SandMaking Plant Eastman Rock Crusher

.jpg)

Rock Crushers Pulverizers Williams Crusher

Typically, a hopper is used to hold and feed the rock to the mill The rock is either gravity fed or a conveyor is used to feed the crusher Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryRaw material preparation is an essential process in cement manufacturing AGICO supplies different cement equipment used in the cement production line, such as impact crusher, cone crusher, hammer crusher, etc Impact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle Impact Crusher Impact Rock Crusher AGICO Cement PlantThe hammer crusher machine completes the crushing material operation by the impact energy During the operation of hammer crusher machine, the motor drives the rotor to rotate at a high speed, and the material enters Hammer Crusher Machine Hammer Crusher

How to Choose a Rock Crusher PowerScreening

As with jaw crushers, these machines are compression crushers that use a stationary and moving piece of steel to break up the material Cone crushers use a rotating head to crush the rock within a steel bowl After initially Simply put, the roller press is the most energyefficient grinding machine on the market Since its commercial introduction into the cement industry by KHD in the 1980s, hundreds of them have been installed in the cement Roller Press KHD Humboldt WedagAGICO jaw crusher machines are finely made to satisfy your needs from pilot projects to mass production! Jaw crushers are popular size reduction machines for the crushing of very hard and abrasive materials such as rock, gravel, metal ore, aggregate, etc It usually requires two crushing stages to make raw materials into cement raw mix Jaw Crusher for Sale Large Jaw Crusher Machines for Mining Cement Brundick, H, “Drying and grinding of extremely moist cement raw materials in the Loesche mill,” ZKG International, No2, 1998, pages 6471Brundick, Horst, and Schäfer, HeinzUllrich, “Loesche mills for clinker grinding,” Asian Cement and Construction Materials Magazine, September 1998, pages 5257Everything you need to know about cement Materials Preparation and Raw

Raw Material DryingGrinding Cement Plant Optimization

Roll presses are also used in, particularly in upgrading existing ball mill circuits as pregrinders to increase production or to reduce specific power consumption in grinding operation Ball mills for cement raw material and coal equipped with a drying compartment adequately air swept with hot gas (2535M/sec above the ball charge), can 2023年2月23日 Crushing Material Turn on the crusher and begin feeding the material into it Keep an eye on the output size and adjust the machine accordingly if needed Make sure to follow all safety guidelines and wear appropriate protective gear Shutting Down and Cleaning Up Once you’ve finished using the crusher, shut it down and clean it up Your Ultimate Guide to Buying a Portable Rock CrusherA 6week modular course is designed to give the course attendee a solid understanding of the grinding system and its auxiliary equipment The purpose of the training is to Identify and understands necessary known and unknown information towards the completed cycle of the grinding system, whether it is a ball mill, vertical mill, or crushing processGRINDING TECHNOLOGY COURSE The Cement Institute2023年2月15日 2 Fine crushing: The materials are sent to a cone crusher for secondary crushing; 3 Sand making and shaping: The finely ground materials enter an impact crusher or a sand maker for the third crushing; 4 Washing: Qualified materials are washed by a sand washer as final product, while the others return to the third crushing process 4 AndesiteWhich Crusher Is Suitable for Your Hard Rock? Fote

.jpg)

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent 2024年8月22日 Other rock crusher machines like roll crusher, impact crusher, jaw crusher, cone crusher, etc【Common Faults Solutions】 【Hammer crusher in cement plant】Impact hammer crusher (cement Hammer Crusher Industry Hammer Mills JXSC 2019年9月27日 There are various types of cement crusher on the market, including jaw crusher, cone crusher, hammer crusher, impact crusher, and etc AGICO Cement can provide all types of cement crusher Our cement Cement Euipment Overview Cement Making 2019年11月4日 Limestone is an important road building material, and is also an important raw material for calcium carbide for burning lime and cement It is a solvent limestone in the metallurgical industry After Limestone Rock Crushing Flow Price JXSC

.jpg)

OK™ Raw and Cement Mill FLSmidth Cement

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeThe Rebel Crusher is the perfect compact mobile crushing screening machine Crush rock, limestone, brick, concrete, asphalt and burns LESS FUEL than the larger, overweight machines The Greatest Concrete Crusher combines an onboard screening system using one diesel and (4)Four onboard discharge conveyors and self cleaning Rebel Crusher For Sale Rebel Concrete Crusher RR Versatile Applications: Franklin Miller's Cement Crushers can be used in various stages of the cement production process, including raw material preparation, clinker grinding, and cement packing Easy Maintenance: Our Cement Crushers are designed with ease of maintenance in mind, ensuring minimal downtime and maximum productivity Cement Crusher and Cement Lump Breaker SolutionsWhen it comes to selecting the perfect crushers, you need to consider a few important factors ie the type of raw materials it will be used for, the budget available for both maintenance and purchase of the crusher, the level of processing that will be required for the raw material, the texture of the rock, thickness, hardness, size, stickiness and even Raw Material Processing Cement Pakistan Company

The Ultimate Guide to Rock Crushers Mellott

2024年5月30日 The crushed material is then expelled from the bottom Gyratory crushers are ideal for hard and abrasive rocks Selecting the Right Rock Crusher Choosing the right rock crusher is crucial It can make a significant difference in your operation’s efficiency and costeffectiveness The right crusher depends on your project’s needsCrushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc Mixing: according to the requirement of clinker, compound desired raw material for cement production line Grinding: grinding all materials into required fineness by cement mill Preparation Of Cement Raw Material Cement Mill, Cement Crusher2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million Review on vertical roller mill in cement industry its Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of Cement Extraction, Processing, Manufacturing

.jpg)

Explore Raw Material Used For Cement

The production of raw cement involves the extraction and procurement of raw materials like limestone and clay or iron ore These materials are then crushed and finely ground to form the raw mix The raw mix is then 2024年6月28日 Rock crushers, specially designed machines, play a vital role in industries like mining, construction, and recyclingThey are responsible for breaking down large rocks into smaller, more Crusher Rock: Exploring the Types of Rock The raw materials are quarried in lump size up to 1 2 m and must be reduced to less than 02 mm This reduction is carried out in two stages, crushing down to 25 mm because the mill is designed for a feed of that maximum size and subsequent grinding Raw materials occur in widely varying forms and a large range of crusher types is availableCRUSHING in Cement Industry INFINITY FOR CEMENT EQUIPMENT2024年7月15日 Jaw rock crusher VS gyratory crusher Different crushing principles Jaw crusher is a compression type of crushing machine The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a compressive force squeezes raw What Are the Differences Between The 7 Types of Crushers?

.jpg)

Understanding Industrial Crushers: Types And Applications

2023年8月1日 Impact crushers earn their name from the impactful way they crush materials These machines can grind large pieces of rock, ore, concrete, or other materials, preparing them for further processing in a ball mill or hammer mill They use a rotor that propels materials into fixed impact plates, causing the material to fracture and break apartGet your mobile crusher We can arrange trucking or you pick it up We also stay with you in the first hours of using the machine to train your staff onsite your material, our expertise We design our machines for easy singleoperator use, so your team will feel confident and safe using your rental crusherMobile Crusher Rental: Concrete, Asphalt, Rock RUBBLE 2024年3月1日 4 Hammer crusher A hammer crusher is a special type of crusher that consists of a rotor with disks on which the hammers are mounted and articulated in the outer area They, therefore, have a design similar to horizontal impact crushers The rotor's high flywheel mass enables the singlestage shredding of feed pieces with edge lengths of up What Machines Do Stone Crushing Plants Need? Fote 2023年2月28日 Primary crushers are also used in some industrial applications, such as in the production of cement and other building materials Secondary Crushing Secondary crushing is the second stage in the comminution process and involves breaking down the material further into smaller pieces that can be handled by the tertiary crushersThe Complete Guide to Primary Crushing, Secondary

.jpg)

Stone Crusher Crushing Rock Machine

2024年9月5日 The crusher successfully processed concrete, bricks, and other materials, contributing to waste reduction and environmental conservation User Satisfaction Survey A user satisfaction survey conducted among stone crusher users revealed high levels of satisfaction with the machine's performance, reliability, and ease of maintenance2014年1月14日 Stage3RAW MATERIAL HANDLINGGRINDING A raw mill is the equipment used to grind raw materials into “raw mix" during the manufacture of cement Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissionsCement Raw Material Grinding Greg Rock Crusher MachineStone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing Rock Crusher Eastman Rock Crusher2022年2月12日 the most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finished product From raw materials to cement Extracting raw materials From raw materials to cement

.jpg)

Dolomite Sand Making Plant And Grinding Machine Eastman Rock Crusher

2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small 2022年1月22日 Cement clinker impact crusher structure Cement clinker impact crusher (hereinafter referred to as cement clinker impact crusher) is mainly composed of machine body, rotor (several plate hammers parallel to the rotating shaft are installed on the rotor) and several arc impact plates in the upper space of the rotor The rotor is directly driven What Are The Cement Clinker Crushing Equipment Eastman Rock Crusher2024年7月17日 There are two crushing methods: rockonrock and rockoniron Roll Crusher Roll crushers crush materials through the compression action of two rotating rollers They are commonly used as tertiary crushers, widely applied in cement, mining, building materials, and abrasive industries for fine crushing and sand makingTypes of Crushers: Choosing the Right One for Each Stage2024年1月11日 Generally, limestone can meet the requirements of cement raw materials after crushing and grinding Machinemade sand has wide applications in the production of machinery manufacturing According to statistics, big steel companies purchase tens of thousands of tons of casting sand annually, which proves it is a potential market for Limestone Crushing And SandMaking Plant Eastman Rock Crusher

Rock Crushers Pulverizers Williams Crusher

Typically, a hopper is used to hold and feed the rock to the mill The rock is either gravity fed or a conveyor is used to feed the crusher Once in the crusher, the material is broken down using a breaker plate and grinding chamber The reduced rock exits the crusher via a conveyor belt or is discharged into a hopper2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryRaw material preparation is an essential process in cement manufacturing AGICO supplies different cement equipment used in the cement production line, such as impact crusher, cone crusher, hammer crusher, etc Impact crusher is a kind of crushing machine which uses impact energy to break materials It is suitable for handling brittle Impact Crusher Impact Rock Crusher AGICO Cement Plant

硫酸钡粉碎设备

--超微超细粉碎机

--200目雷蒙磨股东发生矛盾纠纷怎样陈述格式

--重钙粉机器价钱重钙粉机器价钱重钙粉机器价钱

--碳酸钙石膏粉碎

--ker10060方解石矿石磨粉机

--开一家11人的工厂能赚多少钱

--方解石生产加工细则

--青石是不是花岗岩

--玻纤级高岭土检测 机构

--方解石生产流水线

--硫酸与磷矿石的反应

--辊磨机的内部结构图

--液压粉碎头每小时能破多少方

--世界较大型露天采煤矿有哪些

--欧版磨粉机一呼百应欧版磨粉机一呼百应欧版磨粉机一呼百应

--在爆破区域内放置和使用爆炸材料过程中多少米以内严禁非工作人员进入

--立式矿渣加工设备

--石灰岩开采用什么矿石磨粉机好

--辽阳微粉磨

--韶关那有石头矿石磨粉机

--吉首ZSL150高品质石灰石制粉生产线

--克拉玛依石墨炭黑石灰石制粉

--铝灰化废为宝

--砸石设备报价砸石设备报价砸石设备报价

--哪里有好的磨粉机卖啊

--矿石磨粉机zenith

--磨粉线一般要求是什么岩石

--哪里有粉软锂云母的粉碎机卖

--超细研磨材料

--