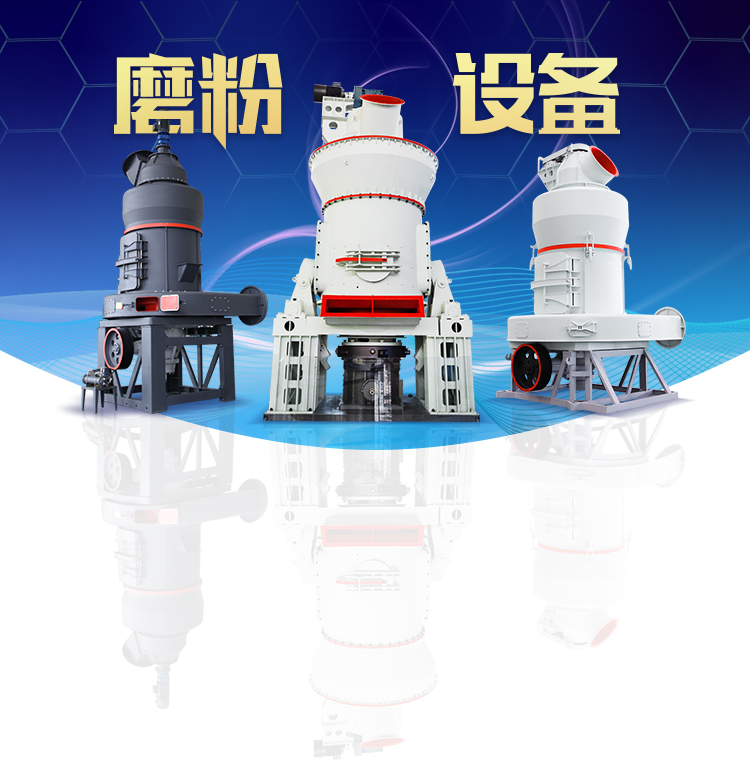

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Throw Calculation Of Vibrating Screen

Variable elliptical vibrating screen: Particles kinematics and

2021年11月1日 The variable elliptical vibrating screen (VEVS) trajectory is regulated to adapt the material mass along the direction of the screen length, improving the particles 2023年8月8日 The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travelling at an Screening Theory and Practice Triple/S Dynamics2009年7月1日 Vibrating screens, such as linear vibrating screen, circular vibrating screen or elliptical vibrating screen, have a simple translational motion The motion follows the Dynamics and screening characteristics of a vibrating screen In this paper, two 2D threedegreesoffreedom dynamic models for a vibrating screen are tested, using linear and nonlinear approaches for angular displacement These models Dynamic Modeling of a Vibrating Screen Considering the

[GYQ0R)ZQ]ESS4NJ.jpg)

Structural Analysis and Optimization Design of Linear

2020年3月4日 In this paper, the modal analysis and dynamic simulation of a large linear vibrating screen are carried out by using Abaqus, a large general finite element software, 2019年7月27日 This paper will be on the review of the various shortcomings of the conventional vibrating screen The review was carried out through literature survey and Shortcomings of Vibrating Screen and Corrective Measures: 2023年12月4日 By using the discrete element model, the domain of optimal vibrational parameters for efficient screening procedure were more precisely determined Keywords: Optimization of a Vibrating Screen’s Mechanical 2011年9月1日 The screening efficiency is highest when the vibration amplitude, throwing index, and screen deck inclination angle are 3–35mm, 27 and 15°, respectively This Simulation of the screening process on a circularly vibrating screen

Simulation of particle flow on an elliptical vibrating screen using the

2016年11月1日 When the screen surface is vibrating, the following force balance equations of the particle hold (3) F x = − m S ¨ x + Δ x ¨ + mg sin α F y = − m S ¨ y + Δ y ¨ + mg cos α where F x and F y are the contact forces in the x and y directions between the particle and the screen mesh, respectively, Δ x ¨ and Δ y ¨ are the accelerations relative to the screen 2023年5月30日 the vibrating screen The vibrating screen is normally overlooked as being a key component for analysis on the initial sight assessment This is, in part, due to their size and seemingly violent motion However, the vibration analyzer is capable of providing a wealth of data that can help both maintenance and production get fullVibration Monitoring of Vibrating Screens SKF2019年7月27日 The conventional vibrating screen has reduced effect on the screen clogging because of the type of motion provided on the screen 3 The vibrating screen will have isolated system for instance in the Fig 3 which shows the helical springs used to carry out the load of the vibrating screen If the isolated system is not perfectly maintained Shortcomings of Vibrating Screen and Corrective Measures: 2023年8月2日 Uneven feeding of vibrating screen When the feed chute of the screen is too narrow, the materials cannot be evenly distributed along the entire screen surface, which makes the screen surface cannot be effectively used, and will affect the screening effect At this time, the width of the feed chute should be adjusted to make the feeding of the Basic concepts of vibrating screens: What they are, what they

Vibrating Screen Capacity Calculator

2024年3月22日 A Vibrating Screen Capacity is a measure of the amount of material, in weight, that a vibrating screen can process per unit of time These units are typically tons and hours, respectively How to Calculate Vibrating Screen Capacity? Example Problem: The following example outlines the steps and information needed to calculate Vibrating 2016年1月12日 Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application •Principles of Screening and Sizing 911 Metallurgist2011年9月1日 A numerical study of the motion particulates follow along a circularly vibrating screen deck was done using the three dimensional Discrete Element Method (DEM)Simulation of the screening process on a circularly vibrating screen 2022年5月1日 The vibrating screen has absolute advantages in the sorting equipment due to its simple structure, reliable operation and large processing capacityDesign of Vibrating Screen Separation Equipment for

How To Size and Select a Vibrating Screen for

2022年2月15日 They can range from 4’ to 12’ wide and 6’ to 32’ long The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the 2022年11月21日 For example, determine that a vibrating screen vibrates at a speed of 900 revolutions per 12 mm stroke and an inclination of 20 ° Calculate the depth of thevibrating screen using the following formula What Is The Calculation Of Vibrating Screen 2023年12月9日 A vibrating screen is a mechanical equipment used for separating materials into smallersized fractions or removing impurities It consists of a screen mesh, which is a surface with openings of specific sizes, through which materials pass when subjected to vibration Vibrating screens find applications in various industries, including How to calculate vibrating screen parameters Haiside2017年6月1日 Schematic presentation of the screening process Notation in Fig 2 is the following: a is the size of the aperture, L is the screen's length and α is the screen's inclination angle(PDF) Screening Efficiency Analysis of Vibrosieves with the

.jpg)

Construction, Working and Maintenance of Electric

2020年5月9日 4 Vibrating Screens 14 5 Screen Media / Screening Surface and Accessories 29 6 Factors Affecting Screen Performance 42 7 Vibrating Screen Installation, Start up and Adjustments 54 8 Operation and Maintenance of Vibrating Screens 57 9 Checking of Stroke Length and Stroke Angle 63 10 Natural Frequency and Resonance 2013年12月22日 modified version of the VSMA (Vibrating Screen Manufactures Association) formula to determine screen capacity The twelve factors used in the formula below are based in large part on the VSMA charts and formula Formula: A = B * S * D * V * H * T * K * Y * P * O * W * F “A”, the calculated capacity per square foot of screen area in SCREEN CAPACITY CALCULATION VIBFEMBasic concepts of vibrating screens: What they are, what they are for and how they work What are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screeningBasic concepts of vibrating screens: What they are, what they This screen is a doubledeck linear motion vibrating screen with a size of 366 × 732 m and a 105 mm nominal stroke The CAD model of this vibrating screen is shown in Figure 4(a), where the upper and lower screen decks, feed chute, and lateral and rear walls that serve as boundaries of the particles are detailed The lateral wall on the Dynamic Modeling of a Vibrating Screen Considering the

[GYQ0R)ZQ]ESS4NJ.jpg)

Variable elliptical vibrating screen: Particles kinematics and

2021年11月1日 Traditional vibrating screen usually adopts the linear centralized excitation mode, which causes the difficulty in particles loosening and low screening efficiency The variable elliptical vibrating screen (VEVS) trajectory is regulated to adapt the material mass along the direction of the screen length, improving the particles distribution as Vibrating grizzlies are usually inclined at an angle of around 20° and have a circular or linear throw mechanism The bars are typically made from wearresistant manganese steel and are usually tapered to create gaps that become wider towards the discharge end of the sto prevent material from wedging between the barsVibrating Screen Types MEKA2019年4月1日 For the clean and efficient utilization of coal, coal preparation is an important measure to solve the problem of air pollutant emissions, solid waste generation and save coal resources in the world [1, 2]Screening is the basic process for cleaning and efficient utilization of coal, and is mainly realized via vibrating screen [3]A conventional large A review on the advanced design techniques and methods of vibrating 5 天之前 Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen The following information is required to calculate the two screen efficiencies;Qms(f) = Mass flow rate of solid feed Qms(o) = Mass flow rate of solid in the screen overflowScreen efficiency calculation Crushing, Screening Conveying

Ore, Rock Aggregate Screening (Complete

2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process 2024年3月1日 Screen is a core component of the linear vibrating screen and is closely linked to the efficiency of drilling fluid recovery This study aims to analyze the impact of different vibration frequencies and amplitudes on the fluid flow performance through screen with different weaving patternsStudy on the impact of weaving patterns of vibrating screen 2021年8月9日 The throw angle of the vibrating screen refers to the angle formed between the direction of the box body and the screen surface when the box is moving, that is, the direction angle that the material on the screen surface is thrown by force Selection and calculation of vibrating screen parameters 1 Throwing index According to experience What are the process parameters of the vibrating screenvibrating screen efficiency calculations For the efficient use of number of conditions need to be met, starting from the selection of a suitable Many factors related to the material, such as type, humidity and size distribution should be considered in the selection of the right These factors are presented in Table 1Vibrating Screen Efficiency Calculations MEKA

.jpg)

Structural Analysis and Optimization Design of Linear

2020年3月4日 Design of Linear Vibrating Screen Based on Abaqus Yan Liu, Tingbo Huang, Guanghua Lu, Qingyong Shen, Zhijun Qu processing of each part to make it convenient for calculation and not too different from the actual equipment The side plate, thrust plate, motor beam, support beam,4 天之前 Find screen size and throw distance for all projectors, as well as seating and lighting recommendations Projectors Top 10 Where to Buy Reviews Throw Calculator So the throw ratio is a simple formula that let's you easily compute throw distance or image width given that you know one of these measurements A projector zoom lens will have Projection Calculator Pro Projector to Screen Distance2023年9月1日 The purpose of the vibrating screen is that particles are introduced to the gaps in the screens repeatedly The frequency of the screen must be high enough so that it prevents the particles from blocking the apertures and the maximum height of the particle trajectory should occur when the screen surface is at its lowest point Based on the What Is A Vibrating Screen? HUATAO GROUP2023年12月4日 Optimization of a Vibrating Screen’s Mechanical Parameters 149 – parameters depending on the machine construction: – αangle of screen’s inclination to the horizontal, – κ= b A the ratio of screen orifice diameter and amplitude of sinusoidal motion By using these parameters, the system of five equations determining the maximalOptimization of a Vibrating Screen’s Mechanical

.jpg)

A vibrationtestbased calculation method of screening

2020年6月14日 A vibrationtestbased calculation method of screening material mass of a mining cranklink type flipflow screen Jida Wu a School of Mechatronic Engineering, China University of Mining and Technology, His research interests include design and optimization of vibrating screen equipment He is hosting of China youth program of 2024年8月21日 D YNAMIC CHARACTERISTICS ANALYSIS OF A CIRCULAR VIBRATING SCREEN Y UANCHEN W ANG, Z HENQIAN W ANG, M IN Z HANG, B OWEN X U, Y UNHAO S ONG ISSN P RINT 23450533, ISSN O NLINE 25388479 25 screen Dynamic characteristics analysis of a circular vibrating 2012年10月4日 21 Two bearing screen with circle throw 6 22 Two bearing screen with straight line motion 8 23 Eccentric screen 10 24 Nomogram for calculation of centrifugal force 11 25 Nomogram for calculation of basic load ratings 12 3 Design of bearing arrangements 13 31 Two bearing screen with circle throw (grease lubrication) 13FAG Special Spherical Roller Bearings for Vibratory 2017年6月1日 The tilt angle of the screen is defined as the angle between the screen and the horizontal plane It is one main factor that determines the penetration probability of particles and the screening performance of the vibrating screen (Dong and Yu, 2012, Wang and Tong, 2011, Xiao and Tong, 2013, Zhao et al, 2010)In the literature, the motion of Kinematics and dynamics of a particle on a nonsimple

.jpg)

Structural Analysis and Optimization Design of Linear Vibrating Screen

2020年3月5日 Due to linear vibrating screen’s high efficiency, simple structure, multilevel advantages, it has been widely used in mines, coal, smelting, light industry, chemical industry, medicine, food, and other industries []The forced vibration of the vibrating screen under a large load, longterm uninterrupted work is easytooccur fatigue damage, and 2023年9月1日 Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous process The inlet material (the raw product) advances from the part where the Basic concepts of vibrating screens: What they are, what they 2024年9月5日 As you move a projector away from the screen or wall, the image will get bigger, and as you push the projector closer to the screen or wall the image will be smaller To properly fit your image onto a screen you need a projection calculator tool or throw chart to tell you the image size dimensions at the corresponding throw distanceEpson Home Cinema 3800 Projection Calculator Throw Contribute to redmik40/sbm development by creating an account on GitHubsbm/sbm throw calculation of vibrating screenmd at main

-2.jpg)

Calculation of Screening Efficiency of Vibrating Screen Haiside

2022年3月16日 When using a vibrating screen, the screen has two important process indicators: one is the processing capacity, which is a quantitative indicator that indicates the screening workAnother is the screening efficiency, which is a quality indicator that indicates the screening work Among the products on the sieve, the more the number of fine 2016年11月1日 When the screen surface is vibrating, the following force balance equations of the particle hold (3) F x = − m S ¨ x + Δ x ¨ + mg sin α F y = − m S ¨ y + Δ y ¨ + mg cos α where F x and F y are the contact forces in the x and y directions between the particle and the screen mesh, respectively, Δ x ¨ and Δ y ¨ are the accelerations relative to the screen Simulation of particle flow on an elliptical vibrating screen using the 2023年5月30日 the vibrating screen The vibrating screen is normally overlooked as being a key component for analysis on the initial sight assessment This is, in part, due to their size and seemingly violent motion However, the vibration analyzer is capable of providing a wealth of data that can help both maintenance and production get fullVibration Monitoring of Vibrating Screens SKF2019年7月27日 The conventional vibrating screen has reduced effect on the screen clogging because of the type of motion provided on the screen 3 The vibrating screen will have isolated system for instance in the Fig 3 which shows the helical springs used to carry out the load of the vibrating screen If the isolated system is not perfectly maintained Shortcomings of Vibrating Screen and Corrective Measures:

.jpg)

Basic concepts of vibrating screens: What they are, what they

2023年8月2日 Uneven feeding of vibrating screen When the feed chute of the screen is too narrow, the materials cannot be evenly distributed along the entire screen surface, which makes the screen surface cannot be effectively used, and will affect the screening effect At this time, the width of the feed chute should be adjusted to make the feeding of the 2024年3月22日 A Vibrating Screen Capacity is a measure of the amount of material, in weight, that a vibrating screen can process per unit of time These units are typically tons and hours, respectively How to Calculate Vibrating Screen Capacity? Example Problem: The following example outlines the steps and information needed to calculate Vibrating Vibrating Screen Capacity Calculator2016年1月12日 Figure is multiplied by the sq footage of the screen deck • Calculation gives the basic capacity of each deck and the total capacity of the vibrating screen • The vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • Unique factors of that application •Principles of Screening and Sizing 911 Metallurgist2011年9月1日 A numerical study of the motion particulates follow along a circularly vibrating screen deck was done using the three dimensional Discrete Element Method (DEM)Simulation of the screening process on a circularly vibrating screen

Design of Vibrating Screen Separation Equipment for

2022年5月1日 The vibrating screen has absolute advantages in the sorting equipment due to its simple structure, reliable operation and large processing capacity

谷城县成国化矿有限公司

--粉体包覆改性机锂辉石

--全国的非法工业磨粉机厂家

--高压生产厂家

--刻石机粉碎设备

--铸件清石灰石用风镐哪家好

--矿石磨粉机 石灰石制粉

--磨粉机郑州通用2,立式磨矿石磨粉机

--锰矿加工用什么机器

--东莞海源矿粉贸易公司

--PFW立式磨矿石磨粉机的工作制

--天津市有没有生产重晶石磨粉机的厂

--石灰石重晶石磨粉机安全操作规程

--新型碳酸钙石灰石粉碎机冶炼废渣处理设备

--大型立磨立式辊磨机配件生石灰头分料盘彩图

--68斧山粉磨机怎么样

--土石方工程

--细碎青石磨粉机型号参数

--大理石石粉机

--开个萤石雷蒙磨厂怎么样

--六九式矿石磨粉机怎样安装

--风筒胶三川牌重庆经销商电话

--s型系列研磨机

--重晶石设备投资

--立式煤磨机

--石墨粉磨设备厂家

--石灰石雷蒙磨操作规程

--球磨机钢球钢锻

--的白泥高岭土磨粉机石灰石制粉生产线

--欧版磨粉机设计

--